One article to understand the application of laser cleaning technology on the inner wall of large and small pipe diameters

Metal pipes play a vital role in maintaining the operation of industries and the convenience of daily urban life. However, there are many hidden safety hazards in the pipeline maintenance process, a large part of which is caused by the corrosion of the inner wall of the pipeline. In the pipeline cleaning application field, the external cleaning of the pipeline is relatively simple, and the cleaning of the inner wall has always been a difficult point. Raycus Laser has achieved a technological breakthrough in the cleaning of the inner wall of the pipeline. Recently, a professional laser cleaning engineer in the Raycus laser live room revealed the secret of this technology.

What are the secrets of this pipeline cleaning technology? In order to solve the problem of cleaning the inner wall of the tube in the market, Raycus provides system solutions in two ways, large and small. The following will briefly show the practical application cases of laser cleaning of the inner wall of small pipe diameter and laser cleaning of the inner wall of large pipe diameter.

This cleaning method uses Raycus's RFL-P200S laser, which has a wide range of cleaning capabilities and is equipped with a rotating cleaning head. Among them, the P200S laser has the characteristics of high average power and high single pulse energy, square or round homogenized spot output, and convenient use and maintenance. It can be used in automobile manufacturing, shipbuilding, petrochemical industry, rubber tires and other fields. The following is the laser The specific parameters of the situation.

Equipment configuration instructions:

(1) 1 type of cleaning head: rotatable cleaning head

(2) Focusing lens: 1064nm wavelength F-Theta lens, focal length 200mm

(3) Laser-RFL-P200S (with optical isolation collimation head)

(4) Cleaning software—Ezcard

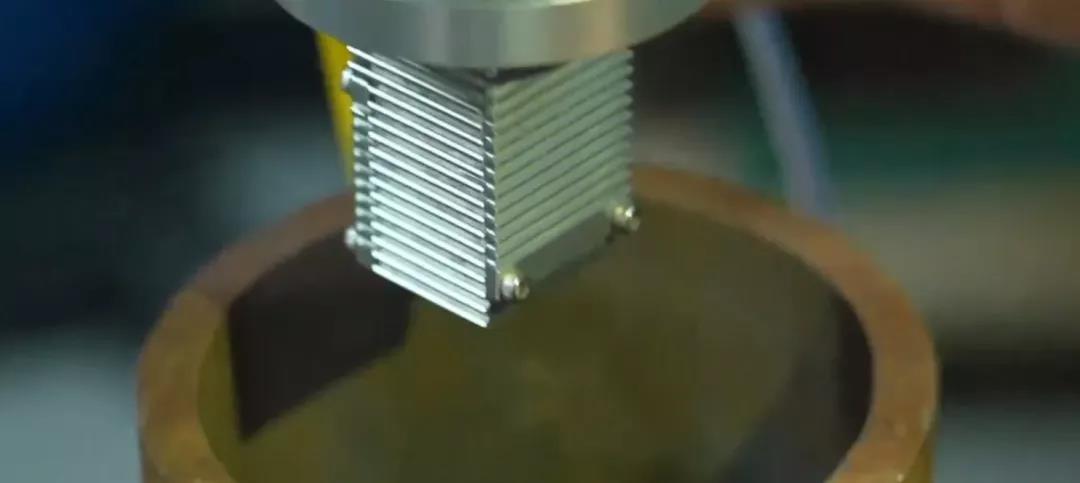

The rotatable cleaning head includes a connecting barrel for fixing the fiber laser, a mirror group for emitting a focused beam, a rotating rod and a motor, which are used to change the spatial distribution of the laser beam emitted by the fiber laser to make the emitted light circular distribution to achieve high-speed cleaning. The support link mechanism includes a support frame, a connecting rod, a sliding sleeve and a roller. The sliding sleeve slides up and down on the rotatable laser cleaning head to drive the connecting rod to zoom, causing the support frame to expand and the roller to walk on the inner wall of the pipe diameter to achieve the goal that the mechanism can be adjusted freely according to the size of the inner wall of the pipe diameter, and the rotatable laser cleaning head is always kept fixed at the center position, so that the emitted light hits the inner wall of the pipe at the same distance.

This set of solutions can be used to clean various pipes with a pipe diameter ranging from 80mm to 250mm. Taking the cleaning pipe with an inner diameter of 100mm and a pipe length of 10m as an example, it only takes less than 3.5 minutes to adjust the linear speed of the cleaning head to 5mm/s.

The customer's on-site cleaning results show that the laser cleaning method can remove the rust and oxide layer of the stainless steel substrate on the inner wall of the tube and present a metallic color. Compared with the traditional method of cleaning the inner wall of the tube, laser cleaning has the characteristics of no pollution and more efficient inner wall cleaning efficiency. Of course, the existing laser cleaning method does not necessarily meet the cleaning of all pipe inner diameters. Different pipe diameters need to be processed with different rotating cleaning heads, and the plan needs to be customized according to the specific size of the pipe diameter.

The large diameter cleaning method adopts the highly efficient and highly integrated Rayco nanosecond pulsed 500w fiber laser source. Using this laser source can clean most of the dirt, and the efficiency is higher under high single pulse energy.

This large-diameter laser cleaning solution can be used to clean residues and large rust spots on the inner wall of large-diameter pipelines. The whole is composed of a 500W nanosecond pulsed laser cleaning integrated system, a rotatable cleaning head, a pipeline walking trolley, a blower and a dust collection device.

The internal structure of the rotatable cleaning head mainly includes an optical system and a circuit system. The optical fiber guides the laser beam into the laser head through the optical fiber connector, and the optical components are installed in the mechanical structure of the rocker arm, and the light spot is focused on the working point by the rocker arm and controlled by the focusing mirror to realize laser processing. When the laser pulse scans the surface of the workpiece at a high speed, the temperature in this area will rise instantaneously and then decrease, generating thermoelastic pressure. Due to the different thermal expansion coefficients of the attachment and the substrate, the surface stress distribution is uneven, so that the dirt, rust or coating on the surface will evaporate or peel off instantaneously, and finally achieve the purpose of efficient and quick cleaning.

The cleaning solution for the inner wall of large pipe diameters is suitable for cleaning various pipes with pipe diameters ranging from 480mm to 1500mm. Taking the cleaning pipe with an inner diameter of 500mm and a pipe length of 10m as an example, adjusting the linear speed of the cleaning head to 1.5mm/s takes less than 1.5h.

The above is the application case of cleaning the inner wall of Raycus large and small pipe diameters. During the display process, the design module of the laser head was analyzed in order to provide a basis for the integrator customer in the design of the laser head. The specific customer can choose the appropriate laser according to the actual situation. The light source is used as a cleaning method.