Precautions for the use of fiber laser cutting machine

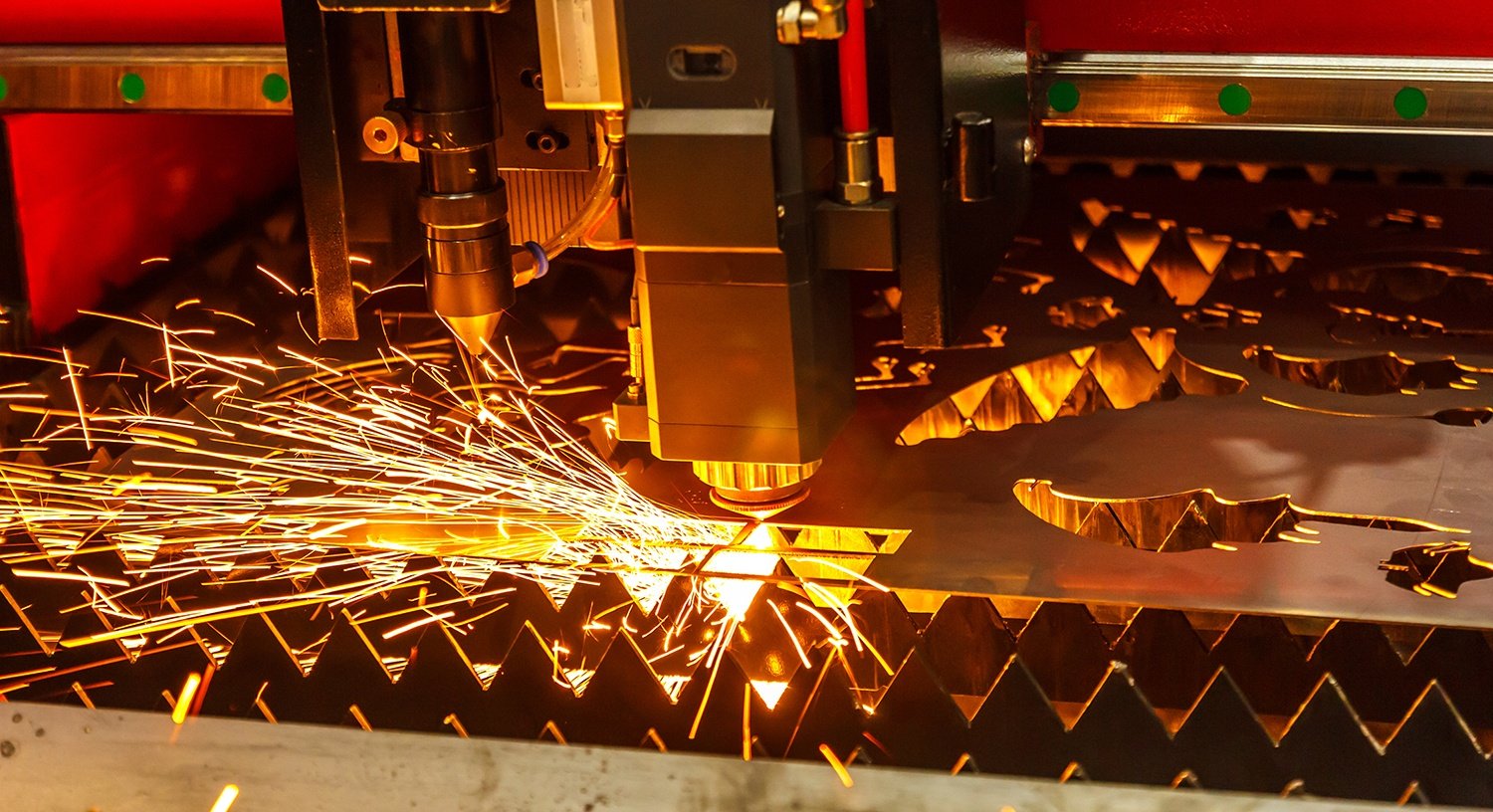

With the rapid development of the metal manufacturing industry, the product quantity and quality requirements of the manufacturing industry are getting higher and higher. The high speed, high efficiency, and high precision of fiber laser cutting machines have become the focus of metal processing enterprises. As a high-precision equipment, fiber laser cutting machine is complicated and dangerous in operation to some extent. Therefore, it is best for the operator to have deep understanding before using the fiber laser cutting machine, so as to make the equipment cutting effect better.

Precautions for the use of fiber laser cutting machine:

1. Frequently check the use of steel belts and tracks. Regularly check whether the steel belt is tensioned, the straightness of the track and the verticality of the machine. If any abnormal condition is found, it should be adjusted and maintained in time. To ensure the cutting quality of the equipment and the safety of the machine.

2. Regularly clean the inside of the machine and the guide rails to remove debris. Be careful to turn off the power before cleaning. Insist on cleaning can maintain the lubricity between the equipment and the guide rails, and make the machine move more accurately during operation to ensure high-quality cutting quality.

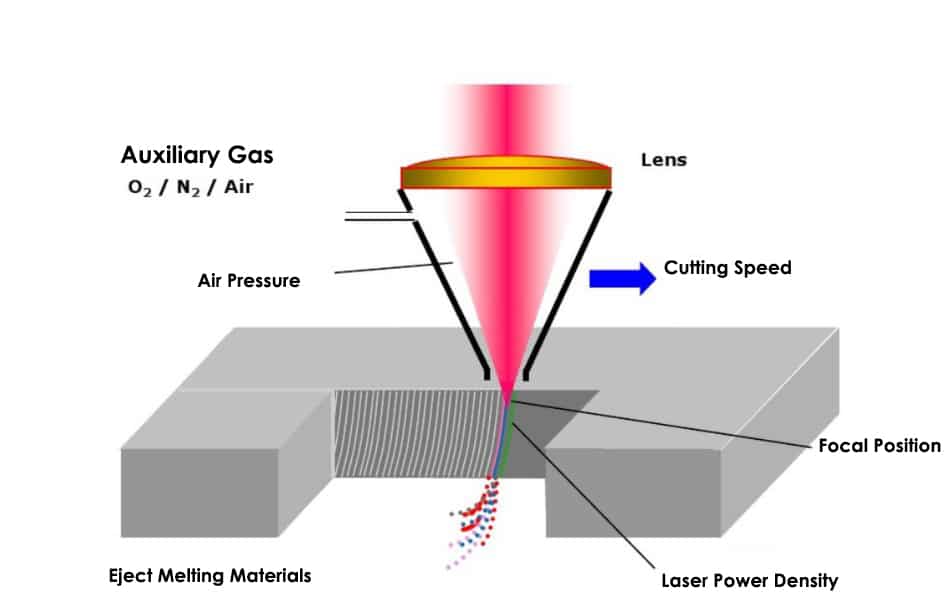

3. Pay attention to the height adjustment of the fiber laser cutting machine. In order to ensure a high-quality cut, the height of the cutting nozzle of the cutting head to the surface of the workpiece must be kept basically the same. However, under different materials, different thicknesses, and different cutting methods, the distance between the cutting nozzle and the workpiece to be cut will vary. This requires the operator to control the height of the cutting head.

4. Eye protection. The wavelength of the light emitted by the fiber laser system is harmful to the eyes, so eye protection measures must be taken. It is best for staff to undergo comprehensive training on proper system operation and safety before work. Staff with no work experience must strengthen the training of operational skills through pre-job training.

Do not operate without any safety training. Laser cutting machines and mechanical equipment have certain safety hazards. Improper operation will not only affect the service life and cutting effect of the equipment, but also seriously endanger the safety of operators. Therefore, the operation must be performed after professional training. Raytu laser provides professional after-sales service personnel who will provide free skills training and guidance for each customer.

Fiber laser is newly developed in the world. It outputs high-energy-density laser beam, which is concentrated on the surface of the workpiece, so that the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and vaporized, and the spot is moved by the numerical control mechanical system to realize automatic cutting by irradiating position, fast speed and high precision.

However, the fiber laser cutting machine is not omnipotent. While seeing its superior processing performance, we must also pay attention to its own current limitations, such as processing material property restrictions and strict processing specifications.

Since the current price of fiber laser cutting machine is not very "friendly to the people", it is necessary to process and maintain the machine frequently during the use process, so as to prolong the service life of the machine and maximize the working efficiency of the equipment.

While doing the daily maintenance of the equipment, strict inspections must be carried out when purchasing the equipment and its parts, so as to fundamentally ensure the normal production of the machinery.

At the same time, if any parts are found to be damaged during the use of the machine, they must be replaced in time. This not only protects the machine itself, but also ensures that the laser cutting machine always maintains an ideal cutting effect.