Raytu laser helps CNC machine tool companies run out of "acceleration"

In the customer's production workshop, two sets of Raytu laser cutting machines are working efficiently. Amidst the sparks, the steel sheets are quickly processed.

There is a "big guy" above them, which is continuously and automatically transporting materials from the adjacent warehouse to the production cutting area, and then automatically transporting the cut workpieces to the finished product area, continuous conveying, continuous cutting, non-stop processing and production cycle, this "big guy" is the "automatic loading and unloading laser cutting flexible production line", it is such a system that enables the production line with 70% of the machine intelligence to realize intelligent production, greatly reducing the labor intensity of the staff, reduce operator safety risks and improve overall production and processing efficiency.

In order to promote product updates and iterations and meet the needs of higher precision and higher work efficiency, the customer urgently needs to introduce automation equipment, and purchased two Raytu 3000W laser cutting machines, creating an absolute advantage in the industry, production efficiency and products. The quality has been greatly improved.

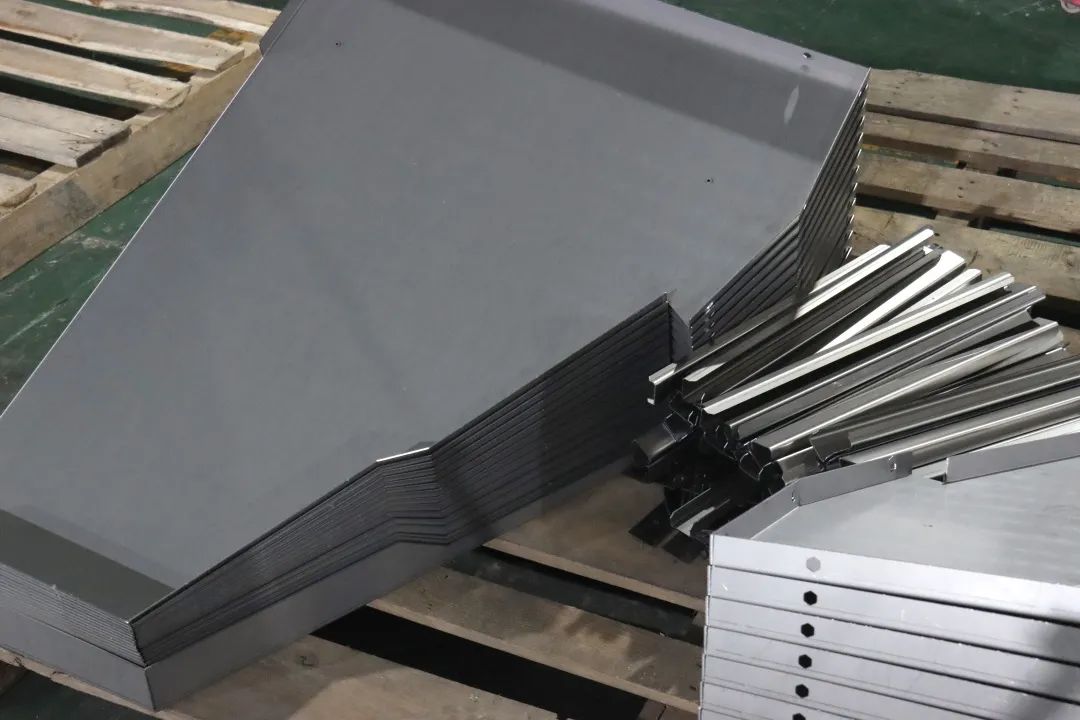

"These two 3000W machines are mainly used for cutting internal and external sheet metal parts of CNC machine tools, chassis cabinets, etc., focusing on 1.0-6.0mm stainless steel processing, with automatic feeding warehouse, to achieve automatic production of feeding-cutting-finished products, it can process about 200 stainless steel plates 24 hours a day, and the cutting workpiece does not require secondary processing, which has achieved great breakthroughs in quality and processing efficiency, and our work is much easier." Zoey, an engineer of industrial intelligence, said with satisfaction.

Since the customer first purchased the Ryatu 3000W fiber laser cutting machine, it has gradually phased out inefficient traditional processing methods. "For the same material, the processing accuracy and speed are different. Now our overall production efficiency has increased by about 30%. The two equipments are processed together, and can be completed in 10 minutes without manual labor, which not only improves the output, but also improves the accuracy. It is also guaranteed. In addition to satisfying the sheet metal processing of its own CNC machine tools, it can also accept external sheet metal processing orders, killing two birds with one stone, and further enhancing the market competitiveness.” Production Manager Lin said.

Talking about another reason for choosing Raytu, "Of course, Raytu's equipment has fast processing speed, high stability, and timely after-sales service response, which is also the reason why we continue to choose Raytu. The fast response ensures our normal production, this has strengthened my trust in Raytu." Manager Lin spoke highly of the after-sales service.