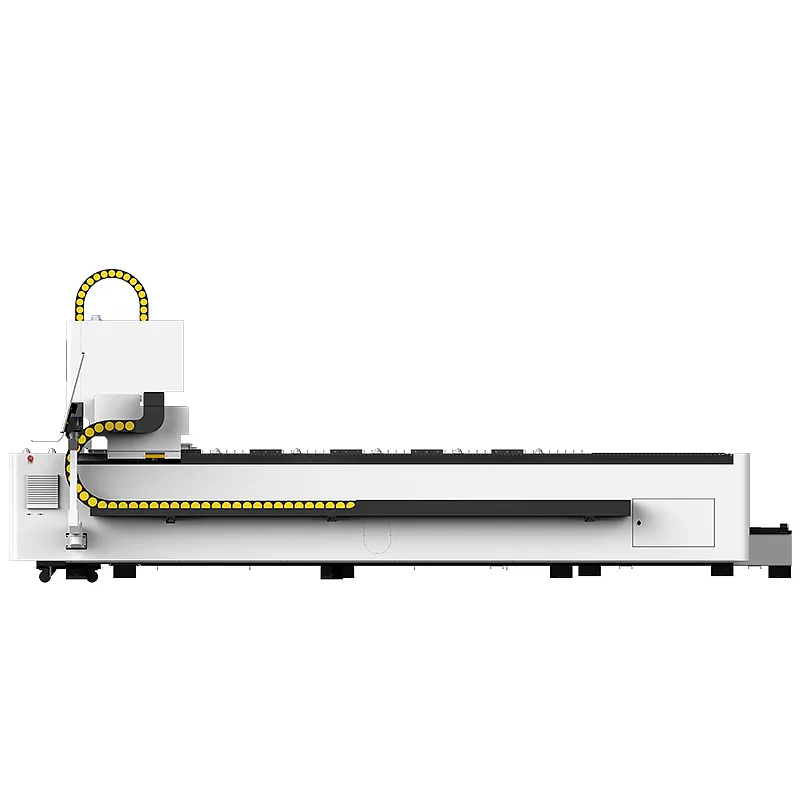

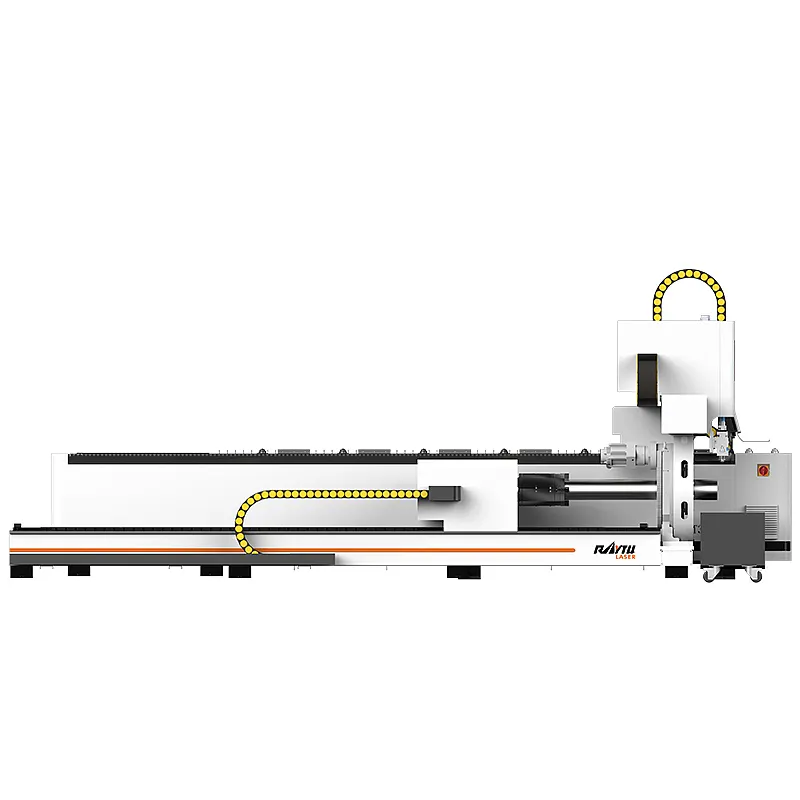

Steel Laser Cutting Machine

Raytu Steel Laser Cutting Machine Description:

When we talk about laser cutting, the mostly applicable metal material is steel. Due to the flexibility of steel laser cutting machine processing, the shape of steel can be processed arbitrarily as required, which also provides more room for steel design. Steel laser cutting products are widely used in people’s lives. The steel laser cutter is low in price and fast in cutting speed and is suitable for all kinds of metal cutting, such as carbon steel, stainless steel, alloy steel, aluminum and alloys, copper-based alloys, titanium and alloys, etc. Similarly, in industrial processing, steel is widely used. As an efficient and high-quality processing tool, fiber steel laser cutting machine has been widely recognized in construction machinery, automobile manufacturing, sheet metal processing and other industries, and has become a necessary metal processing equipmeng in these industries.

Steel Laser Cutting Machine Features:

Branded laser cutting head:

Always maintain a constant high cutting speed at any working temperature. The focal length can be switched quickly in a short time, and the consistency of the TCP can be maintained. Different workpiece thicknesses can be cut through the manual focus position, and the temperature of the sensor can be continuously monitored.

High precision CNC system:

The steel laser cutter can ensure high speed control of 120m / min at 1 μ m resolution. It can process up to 7200 program segments per second and support the machining accuracy of 1nm resolution. The system automatically records the stop program segment, and the user can start processing from the middle of the program at will without manually splicing the program. The feature helps to reduce misoperation and improve work efficiency and can be used for power-off switching as well.

Easy-to-use Automatic layout software:

The software is beginner-friendly and can be used for CAD drawing, DXF / DWG optimization, interactive nesting, automatic programming, cutting simulation and cost calculation. It has the functions of automatic nesting, small pieces filling, large and small pieces nesting. It can be directly converted from DXF graphics file into NC program code. Its common edge cutting connects cutting and nesting of remaining steel plate, which can effectively save steel and improve cutting efficiency.

Steel Laser Cutter Parameters:

Product Recommendation