The advantages of laser welding technology in automotive intelligent manufacturing

At present, industrial manufacturing is relatively mature, and is gradually developing towards more advanced Industry 4.0 stage. The level of Industry 4.0 is fully automated production, also called intelligent manufacturing. The automobile industry is very developed in China. If the industry level is divided into 1.0-4.0, the overall range of automobile industry is between 2.0-3.0, and individual new production lines can reach the industrial level of 3.5. At present, the purpose of intelligent automobile manufacturing is very clear, which is to reduce energy consumption, improve quality, improve efficiency, realize lean production as a whole, and promote the overall manufacturing level of automobile enterprises.

With the rapid development of modern material life, people gradually have requirements for comfort and aesthetics. The aesthetics and precision of automobiles are very important. Traditional welding methods are low in precision, easy to deform, and slow in speed, making it difficult to adapt to the development trend of modern automobile intelligent manufacturing. Laser welding technology uses high-energy-density laser beams and high-density beams as the heat source. This is a welding technology with high precision and high welding efficiency, which is very in line with the trend of modern automobile manufacturing and is more and more popular in the industry.

Advantages of laser welding applications in automobile industry

01 Reduce processing costs

Automobile manufacturing is the assembly of pre-made parts by welding or riveting. Laser welding technology can effectively reduce the number of solder joints. Under the premise of ensuring quality, it can reduce the use of materials, reduce overall weight, and save cost.

02 Improve production efficiency

Laser welding can achieve computer or digital control, high welding accuracy and fast welding speed. The welding speed is 3-5 times faster than traditional welding, which can significantly improve welding efficiency and improve overall manufacturing efficiency.

03 No need for post-processing

The laser can perform small-scale local processing, small heat-affected area, and can be precision welded. The surface of the welded product is smooth and tidy, and the whole has a texture. It can be used without post-processing.

04 The body itself has low loss

Laser welding technology belongs to non-contact welding. The welding method is different from traditional welding. It does not require the use of electrodes. It has very little impact on the loss and deformation of the machine. It can greatly reduce the heat input and reduce the incidence of adverse effects due to heat conduction. .

05 Wide range of welding applications

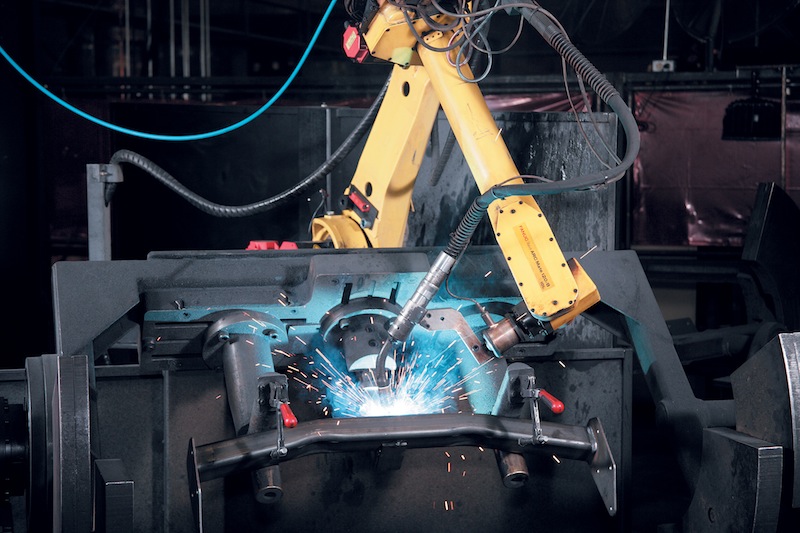

Two different materials can be welded. Common metal materials on the market can be freely combined and welded. Angles that are difficult to achieve manually can be automatically welded with a robotic arm. The welding does not need a vacuum environment, and the welding can be performed in a normal environment.

With the expansion of the global automobile market demand, while the automobile manufacturing process is accelerating, advanced manufacturing technology represented by laser technology is also continuously promoting the upgrading of the automobile manufacturing industry. Laser welding machine technology can help automobile manufacturers improve the quality of welding interfaces, reduce accidents and accident losses caused by joint problems, and help companies achieve cost reduction, efficiency increase, and flexible response to market changes.

With the development of laser application technology, laser welding technology is widely used in many fields such as consumer electronics, packaging, shipping, aerospace, etc., especially in the field of automobile manufacturing, such as automobile door welding, roof, side frame, parts and other applications.