Weihong bus system helps intelligent laser cutting

With the continuous upgrading of laser technology, the stable, intelligent, efficient and convenient Weihong laser tube cutting bus system has been widely used to help intelligent laser cutting. Users who have experienced the tedious and complex laser production process know that worry-free and efficient is by no means easy. Especially in the field of professional pipe cutting, users' demand for automation is increasing day by day. The machine tool also has higher requirements for the axis. The number of common three-chuck machine tool axes has exceeded 10, and even reached 20+.

1. Advantages of laser tube cutting bus system

01. Import and export, allowing to read and write drive parameters

The successful and efficient operation of the laser pipe cutting equipment is inseparable from the high matching of the control system and the driver. The driver parameters can be read and written directly on the system, which greatly facilitates the adjustment of the machine.

02. Support drive alarm details reading

Compared with non-bus, the tube-cut bus system can solve the driver alarm problem in 3 steps.

In terms of user experience, Weihong laser tube cutting bus system has the characteristics of convenient operation, precise control and stable performance.

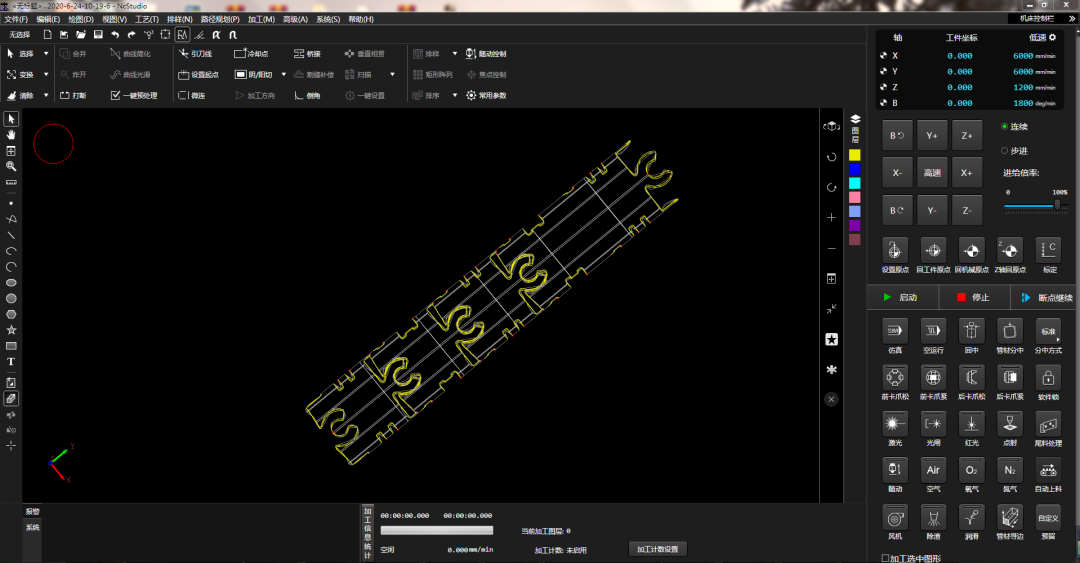

2. TU3200M laser tube cutting bus system

The TU3200M laser tube cutting bus system has a simple and clear control interface, which effectively realizes barrier-free communication between users and equipment, and supports functions such as bus follow-up, servo top material, and front chuck movement.

EtherCAT bus follow-up

EtherCAT bus follow-up, full bus closed-loop control.

Servo top material

It can realize real-time follow-up of the cutting process, and intelligent avoidance of high-speed idling.

Front chuck movement

By avoiding the front chuck to the other side of the cutting head, the remaining tailings are shorter.

3. TU7000M laser tube cutting bus system

The TU7000M laser tube cutting bus system truly realizes zero tailing cutting, gives full play to the processing performance of the equipment, and satisfies the customer's "higher pursuit of laser tube cutting processing efficiency and processing accuracy".

Middle card auxiliary clamping, middle card auxiliary support, front pull material, middle chuck avoidance, long material zero tail material, short material zero tail material.

· Real-time coordinate monitoring, manual attitude switching test, manual motion test of Y-axis and B-axis.

· Full dynamic soft limit, active limit axis movement;

· Automatically identify the interference area and prevent the cutting head from colliding with the chuck;

· Provide feed rate control for easy debugging.

Product iteration promotes the development of the industry. In recent years, with the continuous optimization, upgrading and wide application of Weihong laser tube cutting bus system products, the system will develop towards a more humanized and intelligent development, providing customers with better product experience and assisting metal processing. Upgrade to intelligence.