What are the characteristics of tube fiber laser cutting machine

Most organic and inorganic materials can be cut with tube fiber laser cutting machine. Metal materials which occupies a large part of the industrial manufacturing system can be cut by tube laser cutter without deformation regardless of their hardness. The main characteristics of tube laser cutting machine cutting materials are as follows.

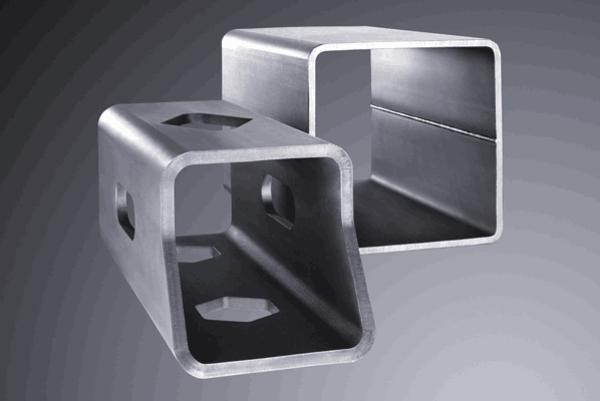

Small deformation of narrow slot workpiece

The laser beam of the tube laser cutting machine is focused into a small point to make the focus reach high power density. At this time, the heat input by the light beam far exceeds the reflection, conduction or diffusion part of the material, and the material is quickly heated to the vaporization degree to form a hole. With the relative linear motion of the beam and the material, the hole continuously forms a very narrow slit. The thermal effect of trimming is very small, and there is basically no workpiece deformation.

In the cutting process of the tube laser cutting machine, the auxiliary steam suitable for the material to be cut is added. In the process of steel cutting, oxygen acts as auxiliary steam to produce exothermic chemical reaction with molten metal to oxidize the material and help blow away the slag in the cutting seam. Of course, for materials with high reflectivity, such as gold, silver, copper and aluminum alloys, they are also good heat transfer conductors, so laser cutting is difficult or even impossible. Tube laser cutting machine has no burr, no fold and high precision, which is superior to plasma cutting. For many mechanical and electrical manufacturing industries, because the modern tube laser cutting machine system controlled by microcomputer program can easily cut workpieces of different shapes and sizes, it usually takes precedence over stamping and forming process. Although its processing speed is slower than that of the stamping die, it does not consume the die, does not need to repair the die, and also saves the time of replacing the die, thus saving the processing cost and reducing the production cost, so it is more economical on the whole.

Non contact machining

The laser beam of tube laser cutting machine forms an action point with strong energy after focusing, which has many characteristics when used in cutting. First, laser energy is converted into amazing thermal energy, which is stored in a very small area and can provide narrow straight edge slits. Secondly, the laser beam does not exert any force on the workpiece. It is a non-contact cutting tool, which means that the workpiece has no mechanical deformation. There is no tool wear, let alone tool conversion; cutting material does not need to consider its hardness, the performance of tube laser cutting machine is not affected by the hardness of the cutting material, can cut any hard material. Thirdly, the laser beam of the tube laser cutting machine is controllable, with high adaptability and flexibility. It is very convenient to combine with the automatic equipment, and it is easier to realize the automation of the cutting process.

Adaptability and flexibility

Compared with other conventional processing methods, the tube laser cutting machine has greater adaptability. Compared with other thermal cutting methods, as a thermal cutting process, other methods can not act on a very small area like laser beam, resulting in wide incision, large heat affected zone and obvious deformation of workpiece. Laser can cut nonmetal, but other thermal cutting methods can't.