What is the normal maintenance process of fiber laser cutting machine?

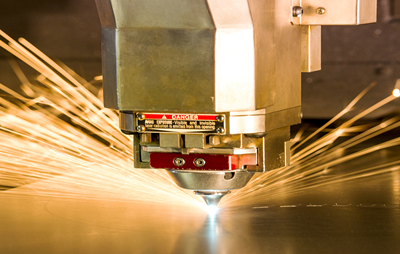

Use a high-power density laser beam to irradiate the material to be cut, so that the material is quickly heated to vaporization temperature and evaporated to form holes, which is laser cutting. As the beam moves on the material, the holes continuously form slits with a very narrow width (such as about 0.1mm) to complete the cutting of the material. Regarding the technical issues of laser cutting, Raytu is here to help you.

Metal laser cutting machine is a technological revolution in sheet metal processing, and it is the "processing center" in sheet metal processing. The laser cutting machine has high flexibility, fast cutting speed, high production efficiency, and short product production cycle. It has won a wide range of customers market.

Fiber laser cutting machine can maintain a good working condition for a long time, and daily maintenance is the key. It can not only effectively reduce the loss of the equipment parts, but also extend the service life. So, what are the normal maintenance procedures for laser cutting machines?

01 Cleaning up the dust removal device

When the dust removal device of laser cutting machine is used for a long time, a lot of solid dust will accumulate in the fan, resulting in loud noise, odor, and unsmooth exhaust. Treatment method: turn off the power, remove the air inlet and outlet pipes on the fan, clean up the dust inside, invert the fan, pull out the blades, clean up the solid dust and restore the installation.

02 Cleaning of machine dust, support bars, etc.

Clean up the dust inside the machine tool every week. Use an air gun to clean up the dust cover, drag chain, electrical cabinet and sheet metal inside the machine tool. Clean the air path components inside the cutting head cover and the cutting head. Note that when cleaning the cutting head, it is recommended to use a smaller air pressure or blow dust at a longer distance. Clean the cutting head waste and iron slag on the guide rails of the working table, and reduce the movement of the equipment exchange table to reduce problem with the chain.

Regularly clean the iron slag of the support bar. If there is enough iron slag on the working table, it will cause the board to be placed unevenly, shake during cutting, and cause the stability of the cut board and the anti-slag on the reverse side. When the support table suffers a large loss during long-term cutting, a limit alarm will appear. It is recommended to make the support table in advance and replace it in time.

03 Cleaning and refueling of machine tool rail rack

The guide rail and linear axis are one of the core components of the fiber laser cutting machine, which play a guiding and supporting role. To ensure the machining accuracy, the guide rails and straight lines are required to have high guiding accuracy and good movement stability. Since fiber laser cutting machine will produce a large amount of corrosive dust and smoke during the processing of the processed parts, these smoke and dust will be deposited on the surface of the guide rail and linear shaft for a long time, which has a great impact on the processing accuracy of the equipment and maintenance of the rack and pinion.

Open the dust cover to clean up the oil and foreign matter on the rack and rail. It is recommended to use diesel to clean the rack of the rail box, and then move the machine tool to wash out the foreign matter inside the slider. After cleaning, wipe off the excess diesel and apply a layer of gear lubricant. Regularly check whether the lubricating oil in the oil tank of the equipment is below the alarm line, and add lubricating oil in time to avoid the wear of the equipment and the change of accuracy caused by the lack of oil for a long time.

04 Water change and cleaning of chiller

The water quality and temperature of the circulating water directly affect the service life of the laser and the cutting head. Note: The maintenance of the chiller must be performed at least 5 minutes after turning off the power of the chiller to avoid the danger of water spray and electric shock. Inspect the filters and heat sinks weekly to clean up dust and foreign objects; check the liquid level of the water tank, and replenish water in time when the liquid level is low; remove dust and decontamination outside the equipment. Inspect and change the medium (distilled water) quarterly; check the dirt in the cleaning tank to ensure a good cooling effect; the PP cotton must be replaced, and the resin tank must be replaced.