Aluminum

Some customers wonder whether laser cutting machine can cut aluminum or not, the answer is definitely yes. In the processing of the cut, notice that aluminum is not resistant to high temperature, processing technology needs to be debugged patiently, at the same time, pay attention to cutting speed. In addition, it is recommended to use nitrogen as auxiliary gas when cutting aluminum plate with aluminum laser cutting machine, because of the special color of aluminum, and in order to ensure the color uniformity of cutting products, nitrogen can well prevent oxidation and retain the characteristics of the material itself, so nitrogen is a better choice than oxygen.

The cutting thickness is relevant to the power of the machine, generally 2000W can cut 6-8mm, 4000W suitable for 12mm, while 6000W can deal with 16mm material. Optical fiber laser cutting is more suitable for cutting aluminum plate, and its wavelength absorption effect of 1064nm is better. After reading these cutting precautions, I believe you can correctly use the aluminum laser cutting machine.

At present, optical fiber laser and YAG laser are widely used in aluminum laser cutting. These two devices have good performance in cutting aluminum or other materials, such as stainless steel and carbon steel. In addition, it should be noted that aluminum has high reflectivity and low absorption of laser, so it is necessary to wear laser protective glasses in the process of processing to protect labor safety.

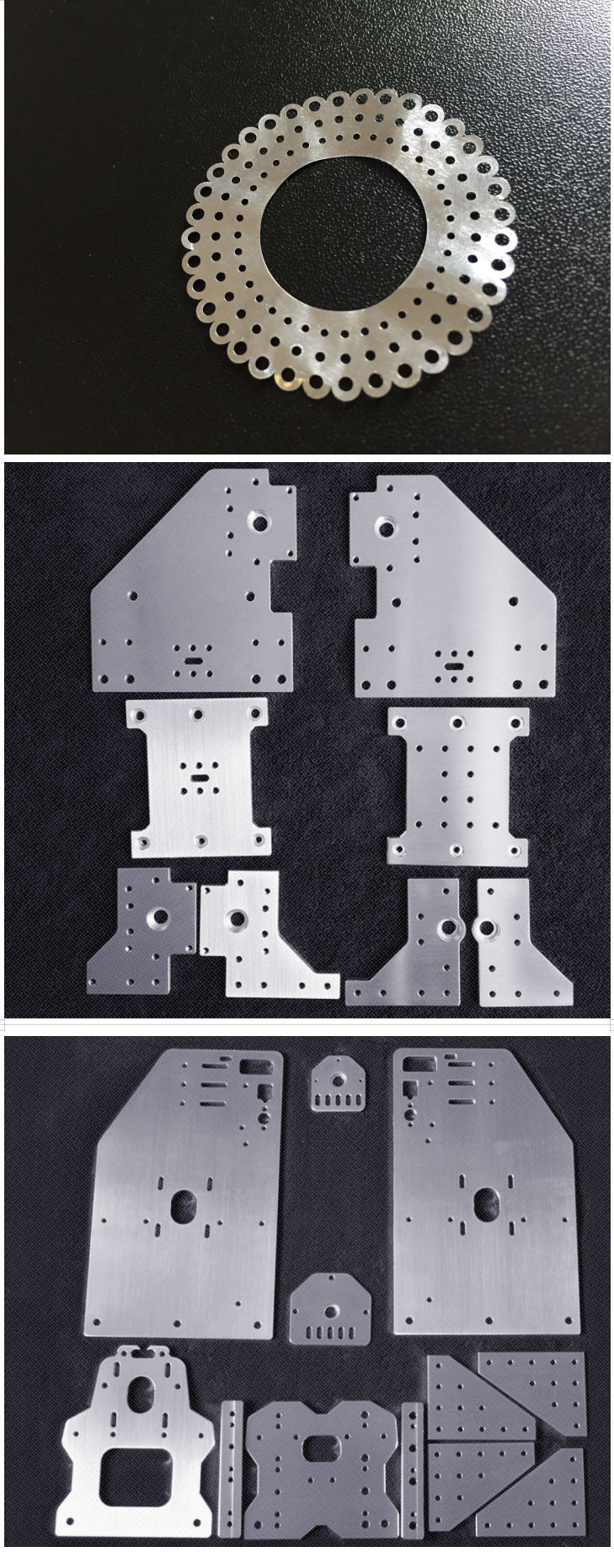

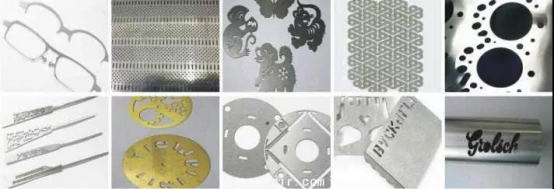

Raytu has been dedicated to aluminum plate cutting for more than 10 years, we can ensure the cutting quality and precision, we also provide good training and after sale service for customers at home and abroad. See some samples of aluminum plate: