Fiber Laser Cutting Machine

Fiber laser cutting has many advantages compared with traditional cnc metal cutting solutions. Advantages mainly include: higher cutting precision and accuracy, higher quality cut edge, narrower incision width, smaller heat affected zone, less material deformation, less material pollution and waste, lower maintenance and repair costs, and higher operator safety. Compared with the traditional cnc metal sheet and tube cutting machine, fiber laser cutter can deal with various designs with higher precision and efficiency. Completely controlled by CNC, fiber laser metal cutting machine can produce complex parts with high tolerance repeatedly and consistently. Laser cutting can also produce high quality cut edges, usually without further cleaning, processing or finishing, thus reducing the need for secondary processing. Raytu laser, as leading manufacturer and supplier of fiber laser machines in China, will provide best quality and factory price laser cutting machine for metal sheets and tubes, including stainless steel, carbon steel, aluminium, copper, galvanized sheet, mild steel, corten steel, silver, gold, ect.

The low heat input of fiber laser cutting machine minimizes the heating area and reduces the degree of thermal deformation. The non-contact nature of the cnc laser cutting process also reduces the risk of mechanical deformation. It is important especially for flexible or thin metal materials, and reduce the risk of material contamination. Due to tighter tolerances, narrower notch width, smaller heat affected zone and smaller material deformation, we can arrange the laser cutting parts more closely on the material. This compact design reduces the amount of material waste, thereby reducing material costs over time.

In the cutting process of fiber laser for general metal materials, due to the fast cutting speed, the thermal deformation of the parts is small, and the dimensional accuracy of the cut parts mainly depends on the mechanical accuracy and control accuracy of the worktable of the laser cutting machine. In the fibre laser cutting process, the high-precision cutting device and control technology are used, and the dimensional accuracy can reach the highest level.

-

-

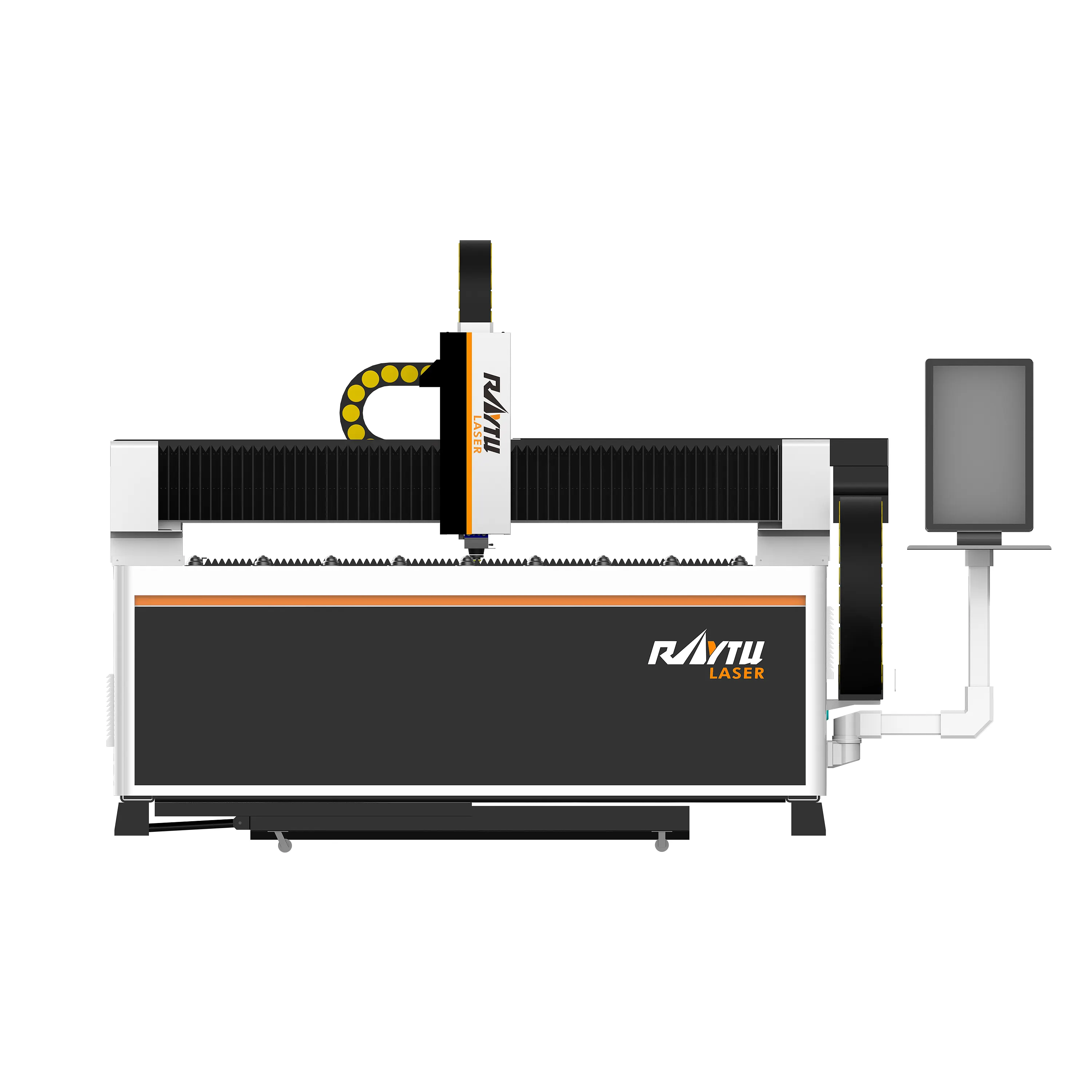

RT-W High Power Single Platform Fiber Laser Cutting Machine 1000W-12000W

-

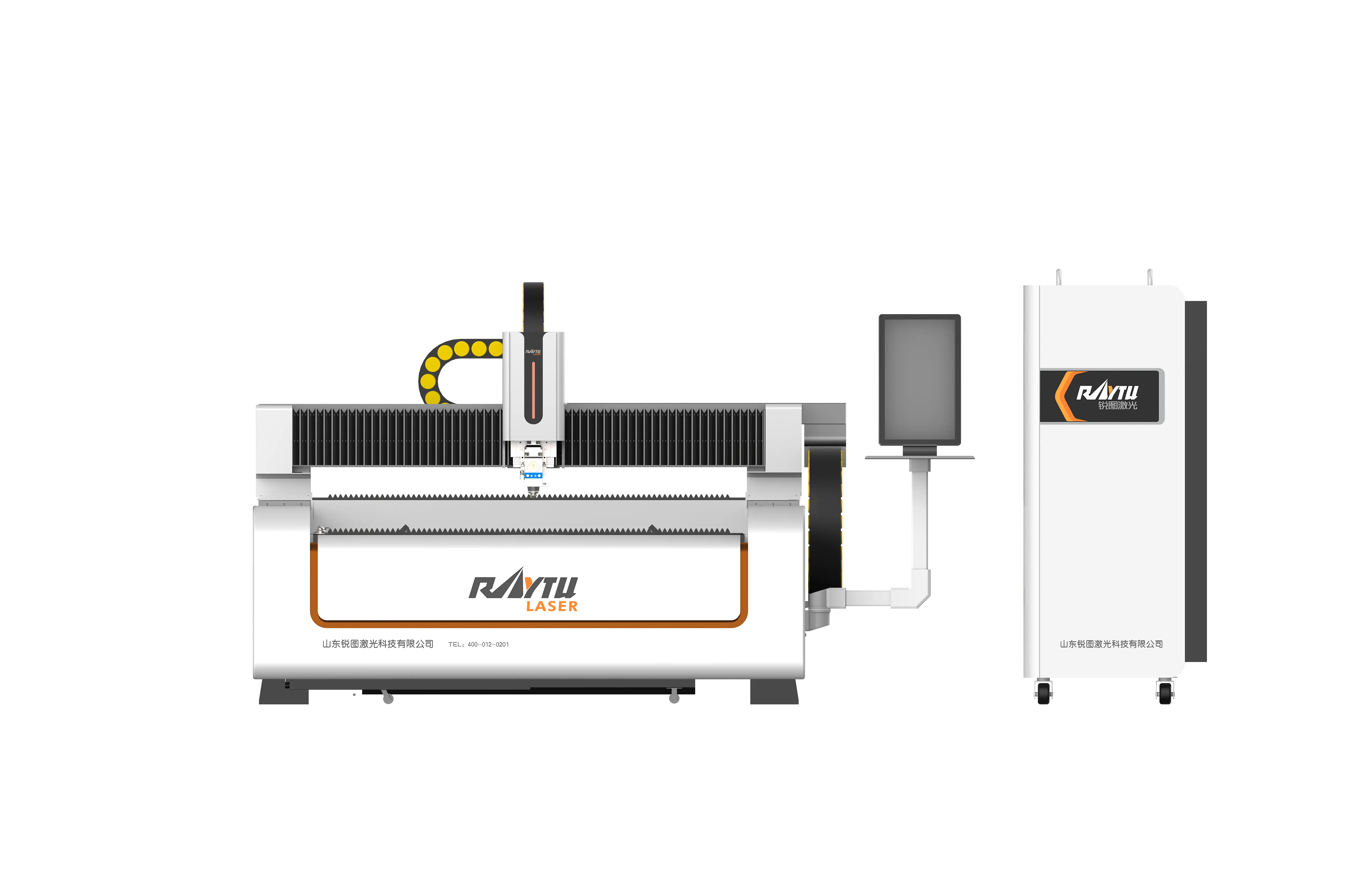

RT-H Medium Power Single Platform Fiber Laser Cutting Machine 1000W-4000W

-

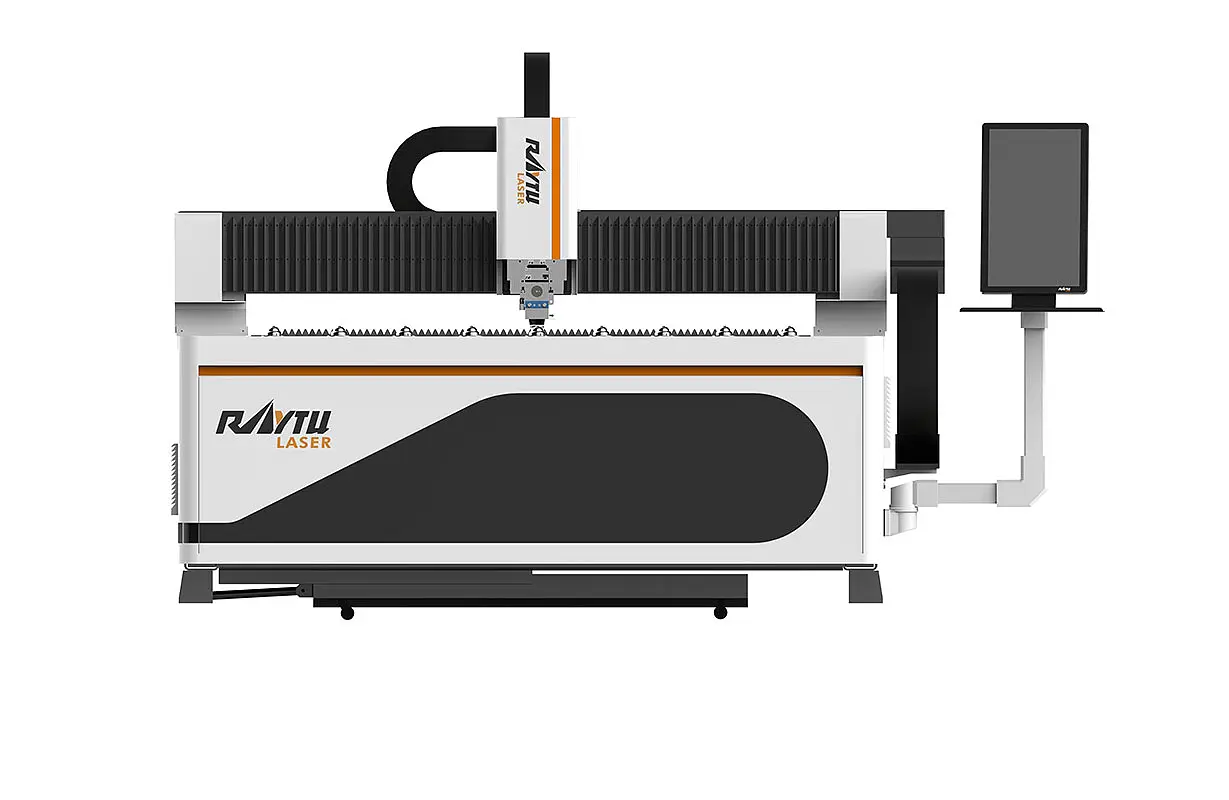

RT-S Protective Cover Exchange Table Fiber Laser Cutting Machine 1000W-20000W

-

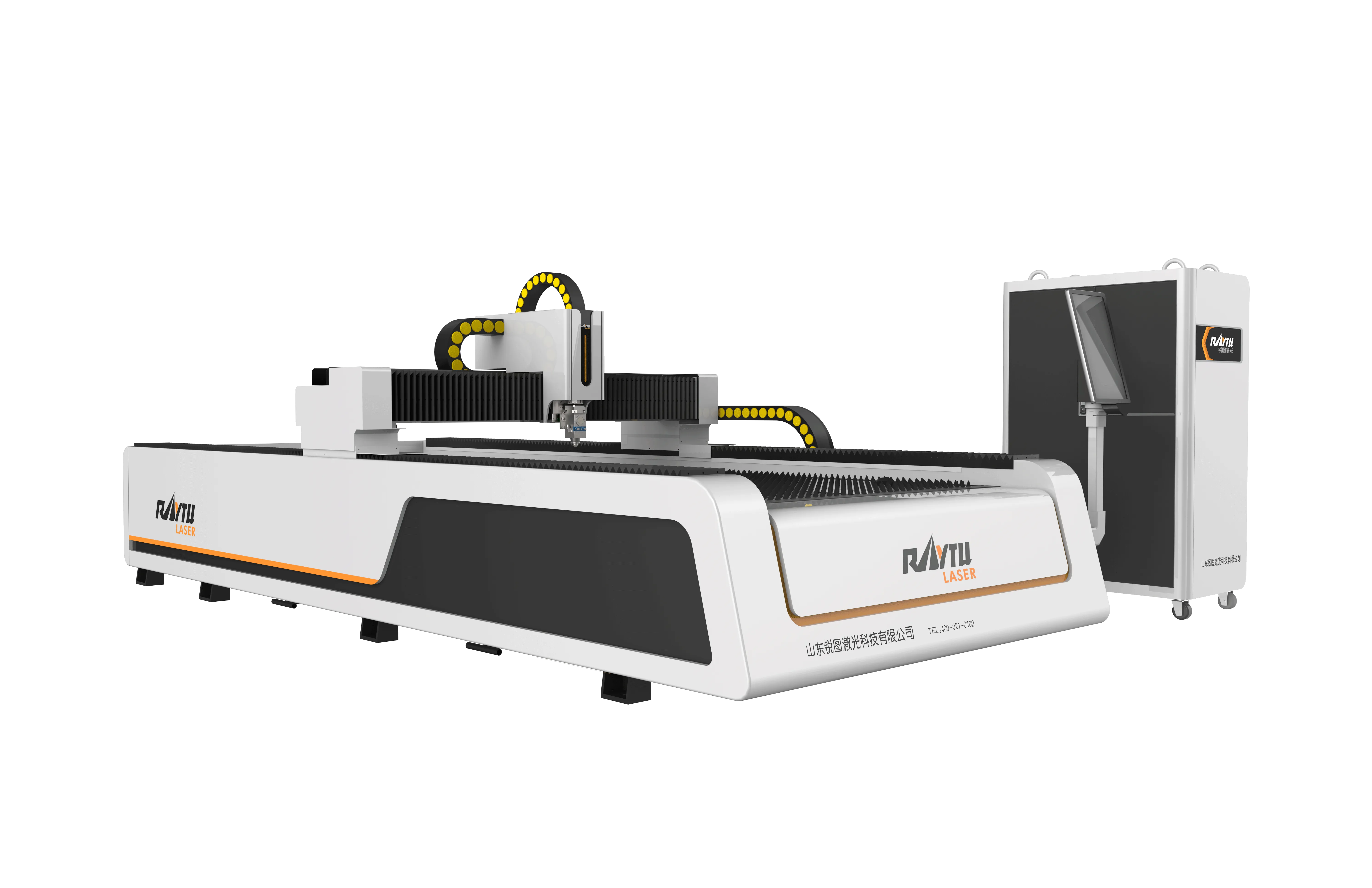

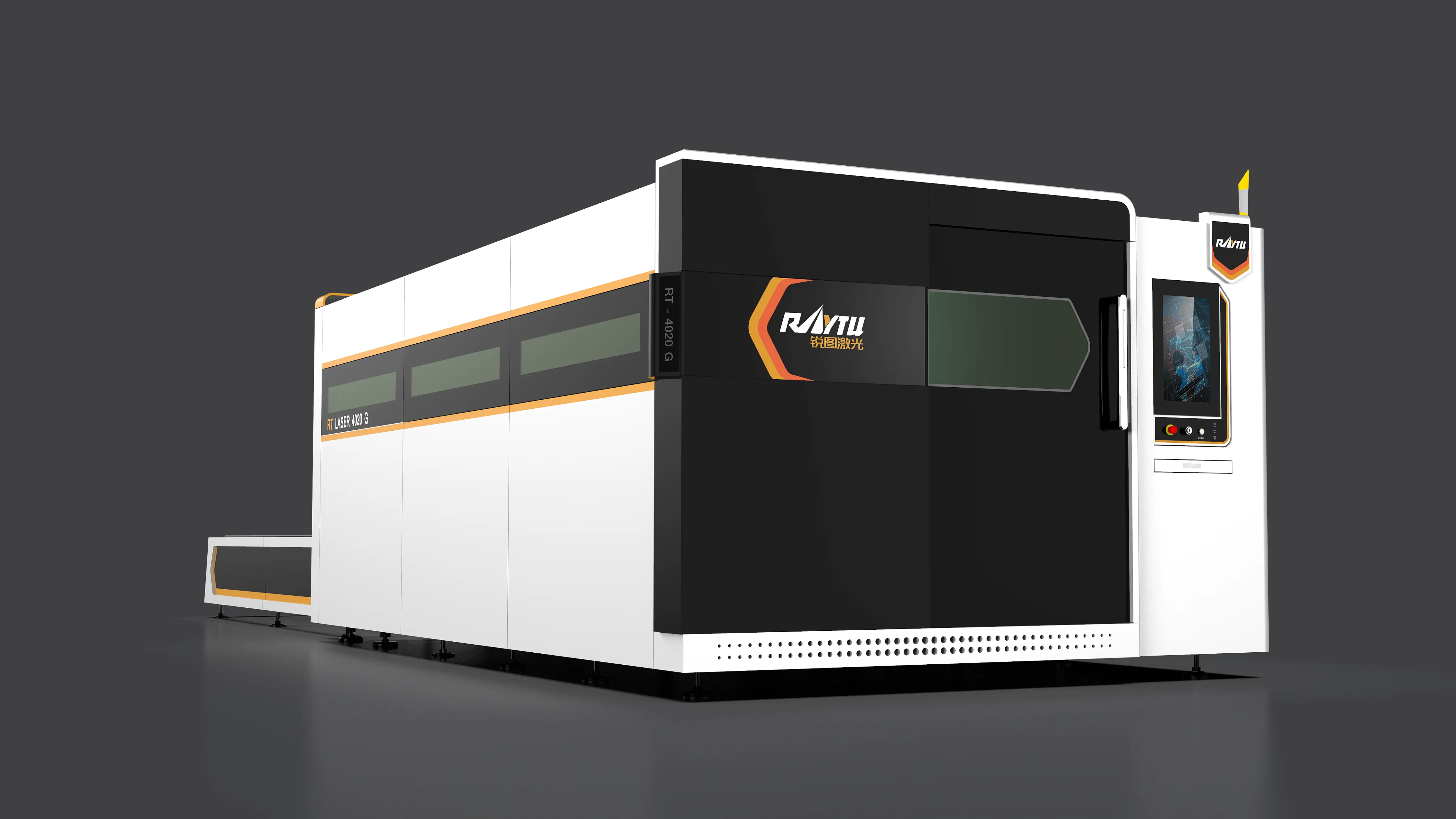

RT-G Enclosed Exchange Table Fiber Laser Cutting Machine 1000W-6000W

-

RT-P Open Type Exchange Table Fiber Laser Cutting Machine 1000W-6000W

-

RT-PT Sheet and Tube Exchange Table Fiber Laser Cutting Machine

-

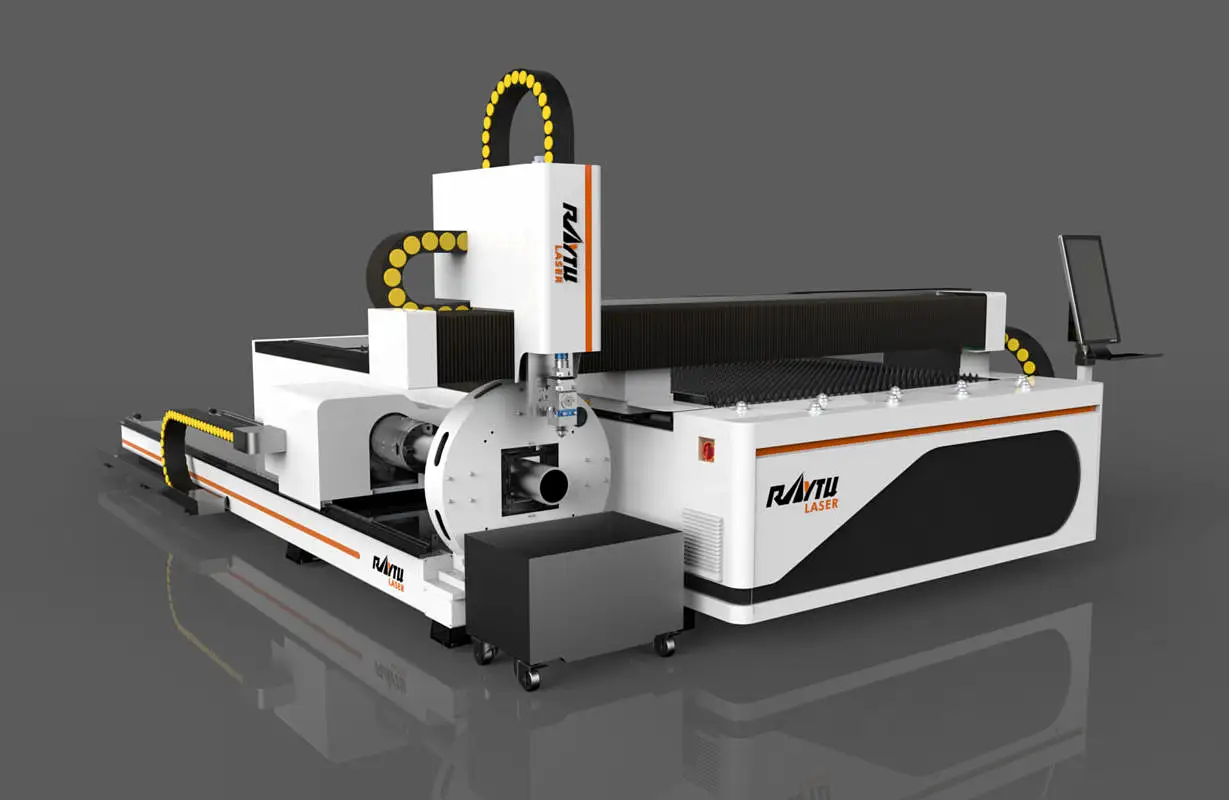

RT-HT Metal Sheet and Tube Dual-use Fiber Laser Cutting Machine

-

-

-

-