Stainless steel

Stainless steel is the most commonly used material in modern society. Here are some examples that stainless steel may appear in our daily life: bowls and chopsticks, kitchenware, bathroom supplies, stainless steel furniture, elevator interior, railings, advertising words, decorations and so on. Stainless steel is popular for its features of rust-protection, anti-corrosion, mechanical properties, durability and colorfastness.

The realization of finished stainless steel products covers mold, grinding, welding and other processing technologies, which costs a lot of manpower, mold and time. Thanks to the development and application of laser cutting and laser welding technology, stainless steel processing becomes much easier while the quality is higher. With the application of stainless steel laser cutting machine, the cutting efficiency, cutting quality and cutting precision have been greatly improved.

Raytu laser cutting machine for stainless steel has the advantages of superb beam quality, high cutting precision, smooth kerf, and is not restricted by complex and intricate cutting contour. No need of labor-consuming pre-processing in most cases, the production efficiency of laser cutter is 5-10 times higher than that of traditional stainless steel processing method, which can meet the demand of rapid proofing and mass production capacity.

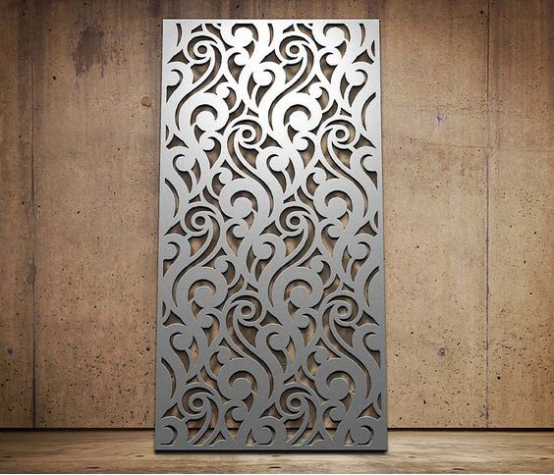

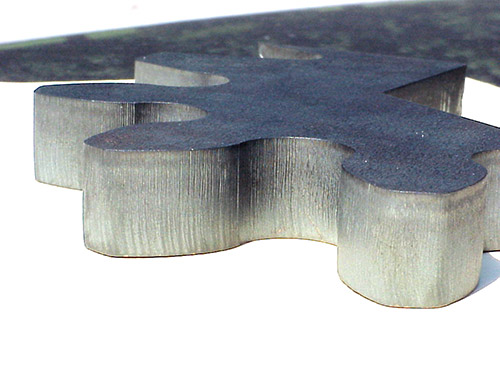

Here are some samples of stainless steel cut by Raytu laser cutting machine: the thickness (mm or inch) varies depending the watt of the machine.