What is the reason why the lens of the laser cutting machine is often burned? How to deal with it?

The laser cutting machine is believed to be familiar to everyone. As the thickness of the processing metal plate gradually increases, the application of thousands of tiles of laser cutting machines is becoming more and more wide. Users often ask why the laser cutting head protection lens will be burned during the operation of the laser cutting machine. Phenomenon. So what causes the laser cut head protection lens to burn? How to effectively prevent the protective lens from burning?

1 What is the role of laser cutting head protection lens?

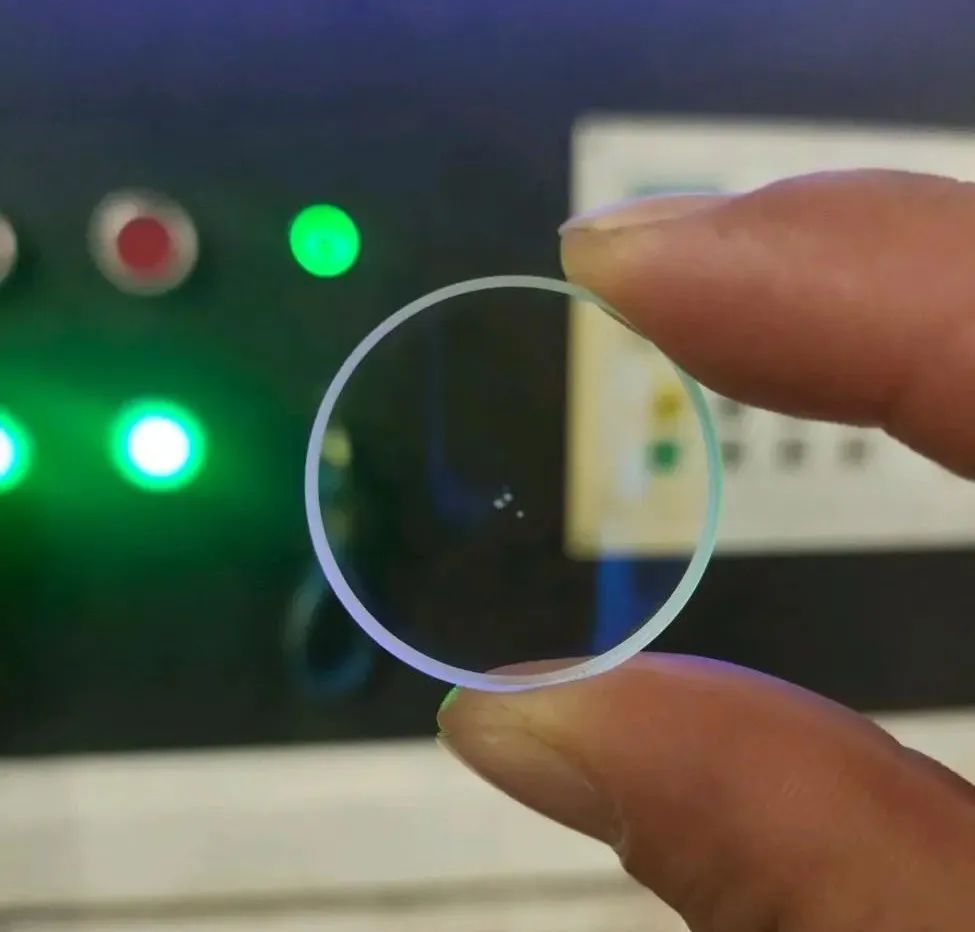

A protective lens is a very important precision component in the light road system of the laser cutting machine. The laser cutting head will gather a large amount of energy during processing. To block the dust and slag splashes, protect the internal light path and core components of the laser cut head. Therefore The lens, effectively protects the laser-cutting head and is not damaged.

2 What are the reasons and solutions to the cause of the lens?

Choose a protective lens corresponding to laser power. The quality must be selected. Don't be cheap.

Check whether it is caused by the residue, and if there are many workpieces, the parameters are changed to a short distance.

Check whether there is dust in the pipeline, clean all the lenses in the cut head, then put a dustless cloth on the pipe, open the gas for a while, and blow the dust as much as possible.

Check whether the surface of the cutting workpiece is flat and deformed.