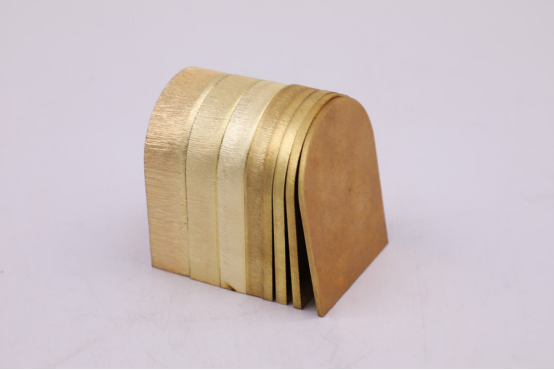

Brass

High reflective metal materials have always been difficult to cut by laser cutting machine, including brass, copper, aluminum, gold and other metal materials. It is a big issue for laser cutting machine manufacturers to solve the problem of cutting high reflective materials.

Why is it difficult for laser cutting machine to cut high reflective metal materials? Because the high-intensity reflection will damage the optical parts on the laser cutting machine equipment, but it does not mean that the high reflection metal materials cannot be cut. Now the problem of brass laser cutting has been solved. Let's share some cutting experience.

As we all know, copper is a kind of material with heat conduction performance. Before processing this kind of material, we should first analyze its performance and material, and understand the performance of each processing material, which is a necessary skill for laser cutting machine operators. Therefore, we need to master the performance of brass, such as its heat transfer performance, reflectivity and so on. When we understand the characteristics of the materials we need to cut, we can better analyze the cutting solution - adding nitrogen and oxygen auxiliary gas.

Why is it necessary to add auxiliary gas to cut high reflection metal materials? When the laser cutting machine cuts metal brass, the added auxiliary gas reacts with the material under high temperature, increasing the cutting speed, for example, using oxygen can achieve the effect of combustion supporting. For laser cutting equipment, nitrogen is an auxiliary gas to improve the cutting effect. For brass materials under 1 mm there is no need to worry about whether it can be cut off. At this time, we should pay attention to the processing effect, so nitrogen is the best auxiliary gas. When the thickness of copper reaches 2mm, it is impossible to process with nitrogen. At this time, oxygen must be added to support combustion and oxidize it to realize cutting.