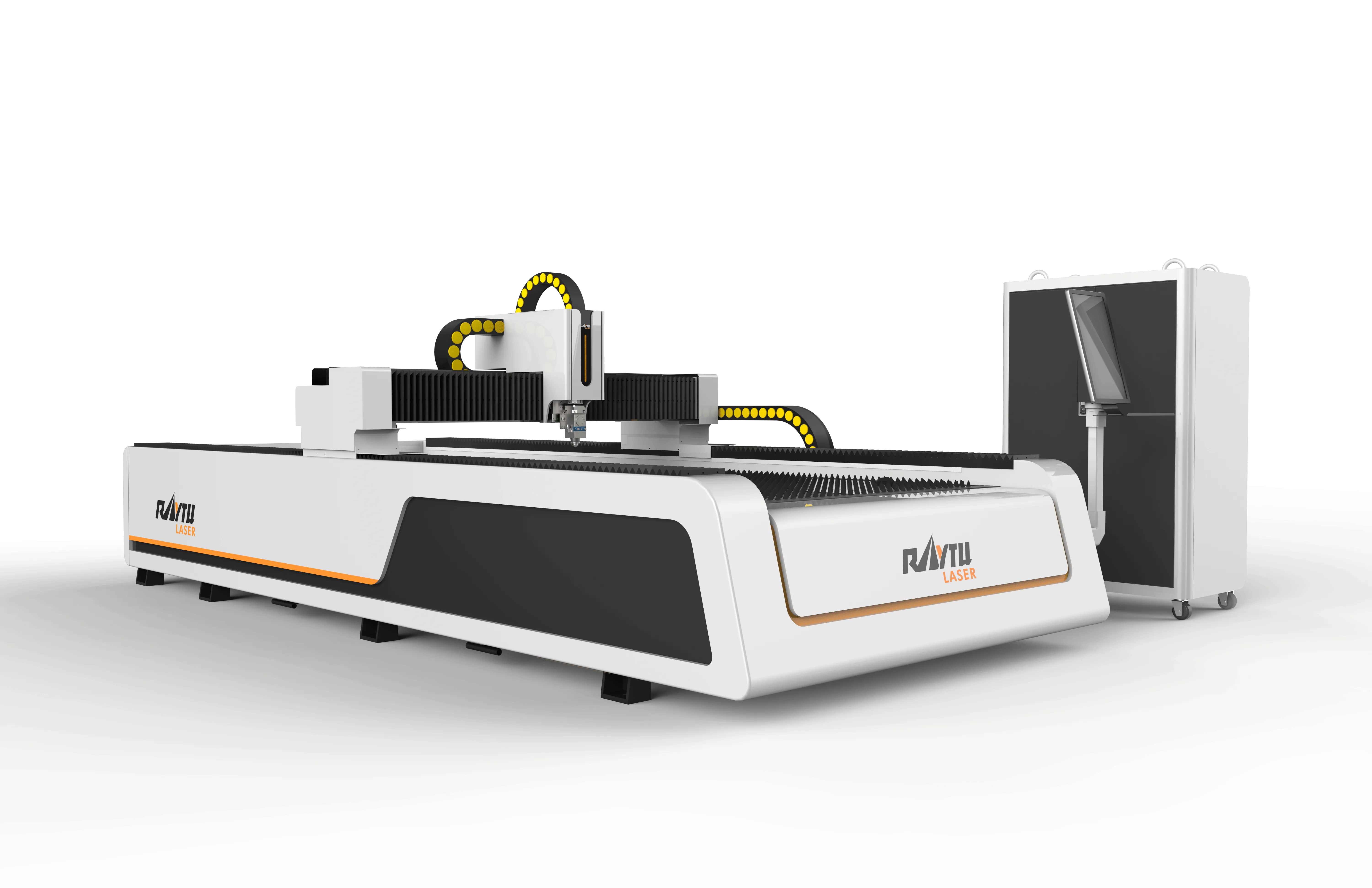

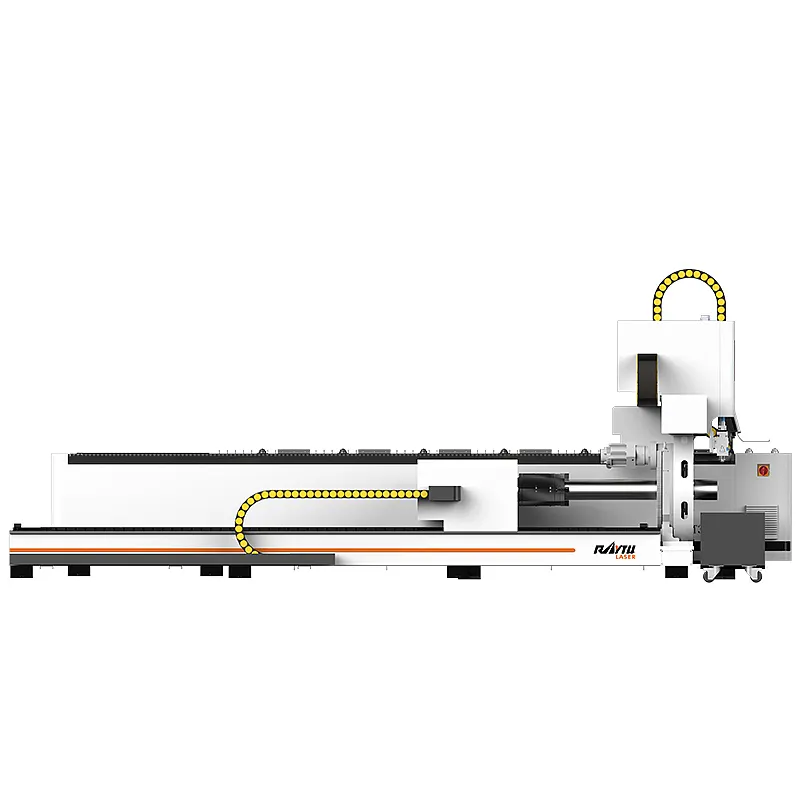

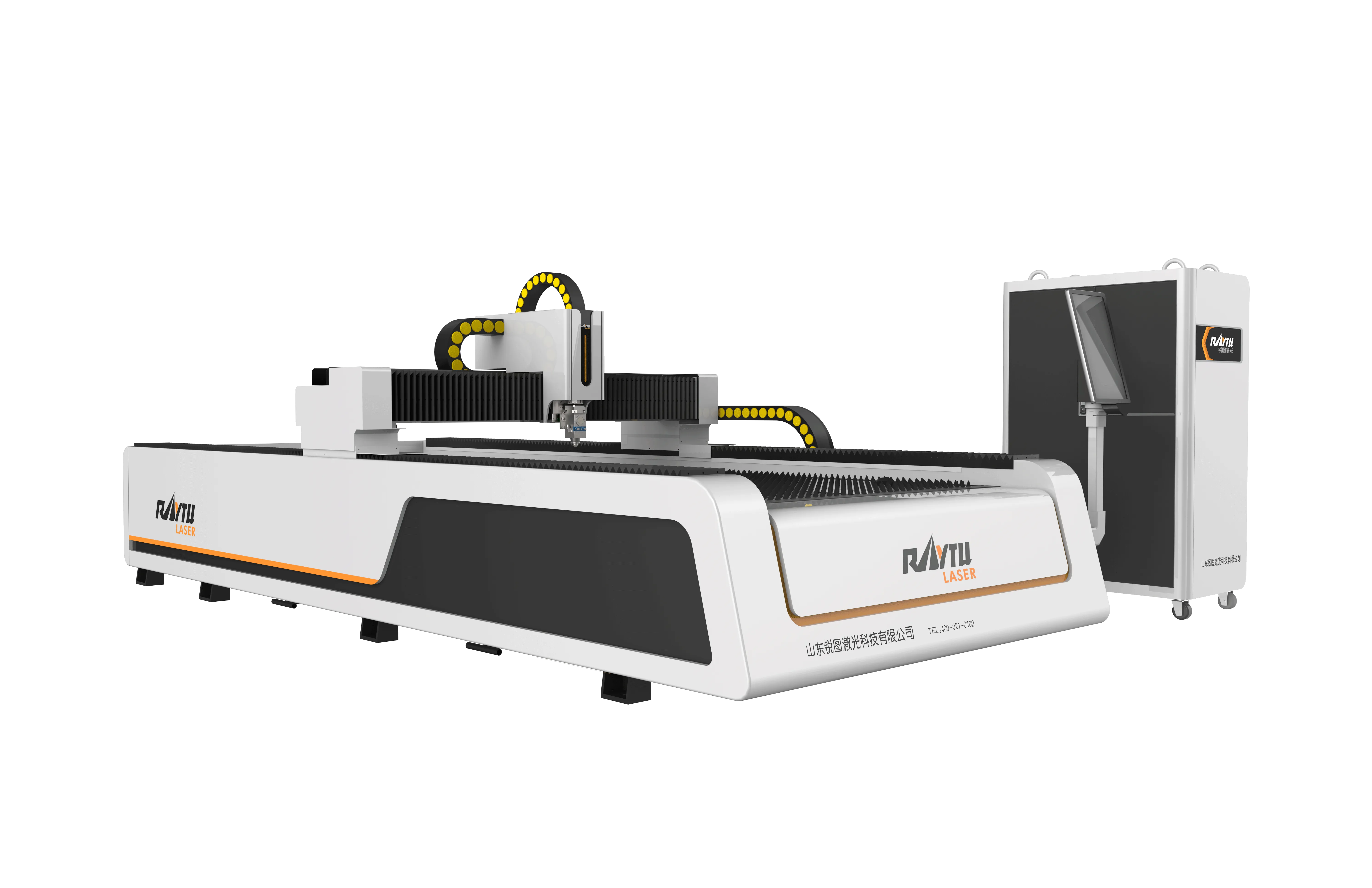

RT-W High Power Single Platform Fiber Laser Cutting Machine 1000W-12000W

About W-Series

Raytu W-Series is high power single table fiber laser cutting machine designed for cutting thick metal sheet with high accuracy and high efficiency. The power of Raytu W ranges from 1000W to 12000W while H-Series power range from 1000 watts to 4000 watts. W series features for intelligent centralized control system, heavy welded sheet bed made of extra thick sheets, auto focus head, automatic lubrication and intelligent zonal dust removal system.

Features

Heavy welded sheet bed made of extra thick sheets

The bed is welded from 8-12mm super-thick carbon steel sheet and is subject to high-temperature annealing, vibration treatment and natural aging in order to completely eliminate the stress in welding and machining, greatly increase its strength, rigidity, high accuracy and wear resistance, can be used for 20 years without deformation. The sheet bed has significant advantages over the tube bed, such as greater weight, strength and reliability, no vibration during operation and, as a result, provides a stable, high-quality and accurate cut.

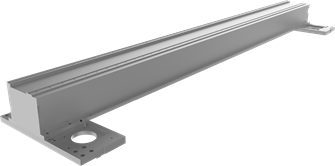

Aviation aluminum gantry

The entire gantry is treated with a T6 heat treatment process to give the gantry maximum strength. Enhanced machine base, lightweight gantry finished by cast aluminum, higher speed operation, precision processing with Japanese equipment, high temperature aging treatment, hollow structure, no heat-deformation.

Laser cutting head with autofocus

The autofocus laser cutter head has a built-in motor drive. The focus lens is driven by a linear mechanism to automatically change position within a specified range. Continuous focus can be set by the software to complete fast punching from thick sheets and cut sheets of different thicknesses from different materials.

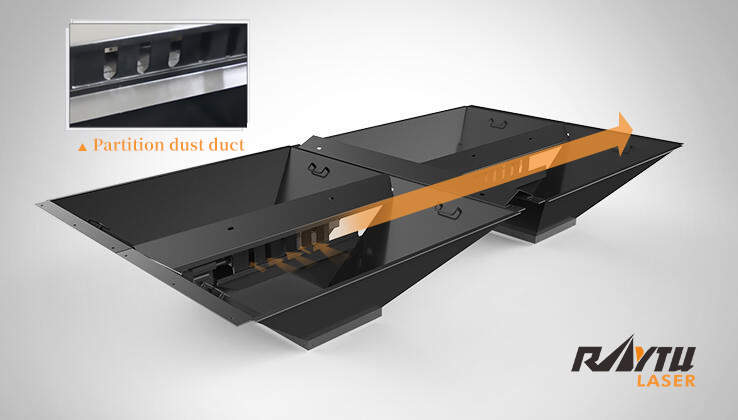

Intelligent zone smoke exhaust system

The zonal smoke exhaust system consists of the sectional design of the cutting table and built-in ventilation ducts. Each section has pneumatic exhaust vents, slag collection funnels and pull-out trays for waste disposal. Waste generated during the cutting process falls between the table lamellas into funnels and settles in sliding trays for collecting slag.

Intelligent centralized automatic lubrication system

The lubrication time and frequency can be adjusted by central control system, integrated multi-point lubrication for slideways, sliders, racks, etc., and automatic return and collection of used lubricating fluid.

W-Series Parameters

Product Recommendation