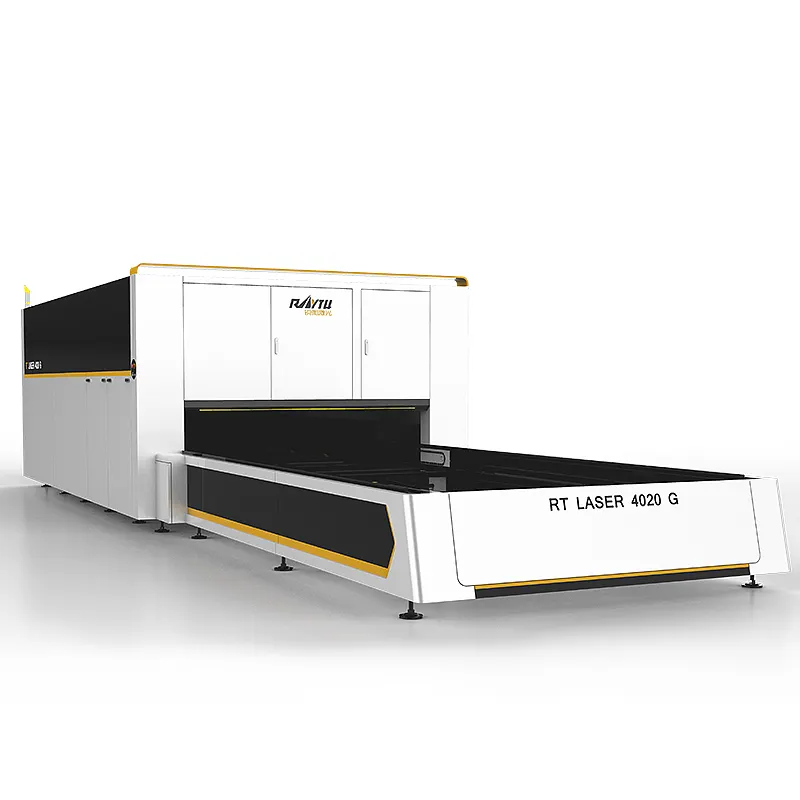

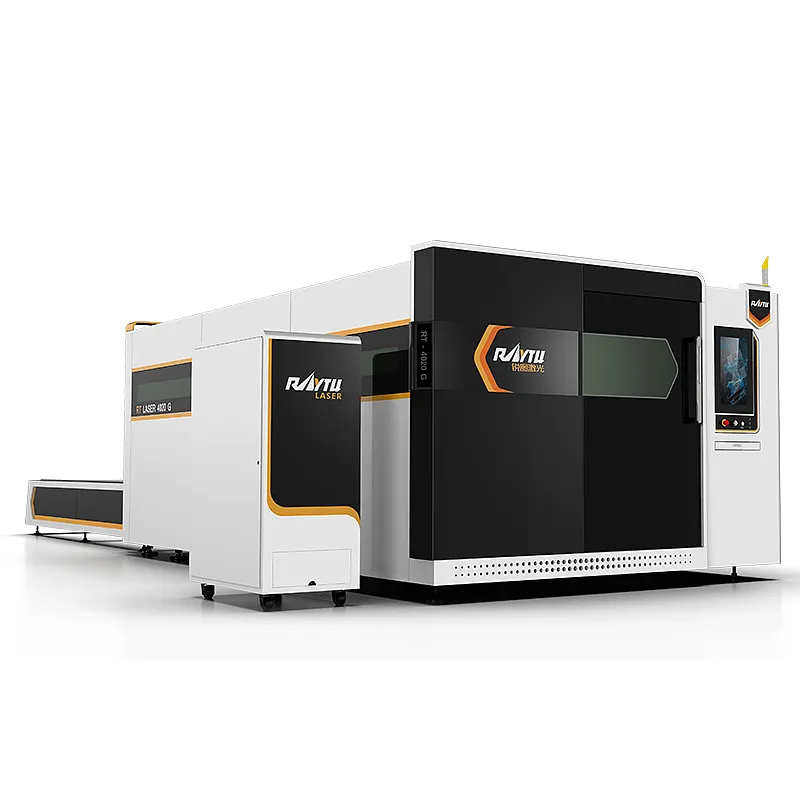

RT-A Economic Single Bed Metal Laser Cutting Machine

Description of the A series machine:

1 Fields of application

Sheet metal processing, advertising sign manufacturing, hardware box and electrical cabinet

manufacturing, sheet metal household appliances and kitchenware, metal products industry and

other fields.

2 Heavy welded bed with T6 heat treatment

The frame is welded from high quality thick pipes, has good rigidity, excellent seismic performance. The

welded tube bed is suitable for cutting thin sheet metal and has better maintainability.

The bed is subjected to high-temperature annealing, vibration treatment and natural aging in order to

completely eliminate the stress during welding and machining, greatly improving its strength, rigidity, high

precision and wear resistance.

Professional software "ANSYS" for finite element analysis, design optimization, improvement of the dynamic

characteristics of the bed system.

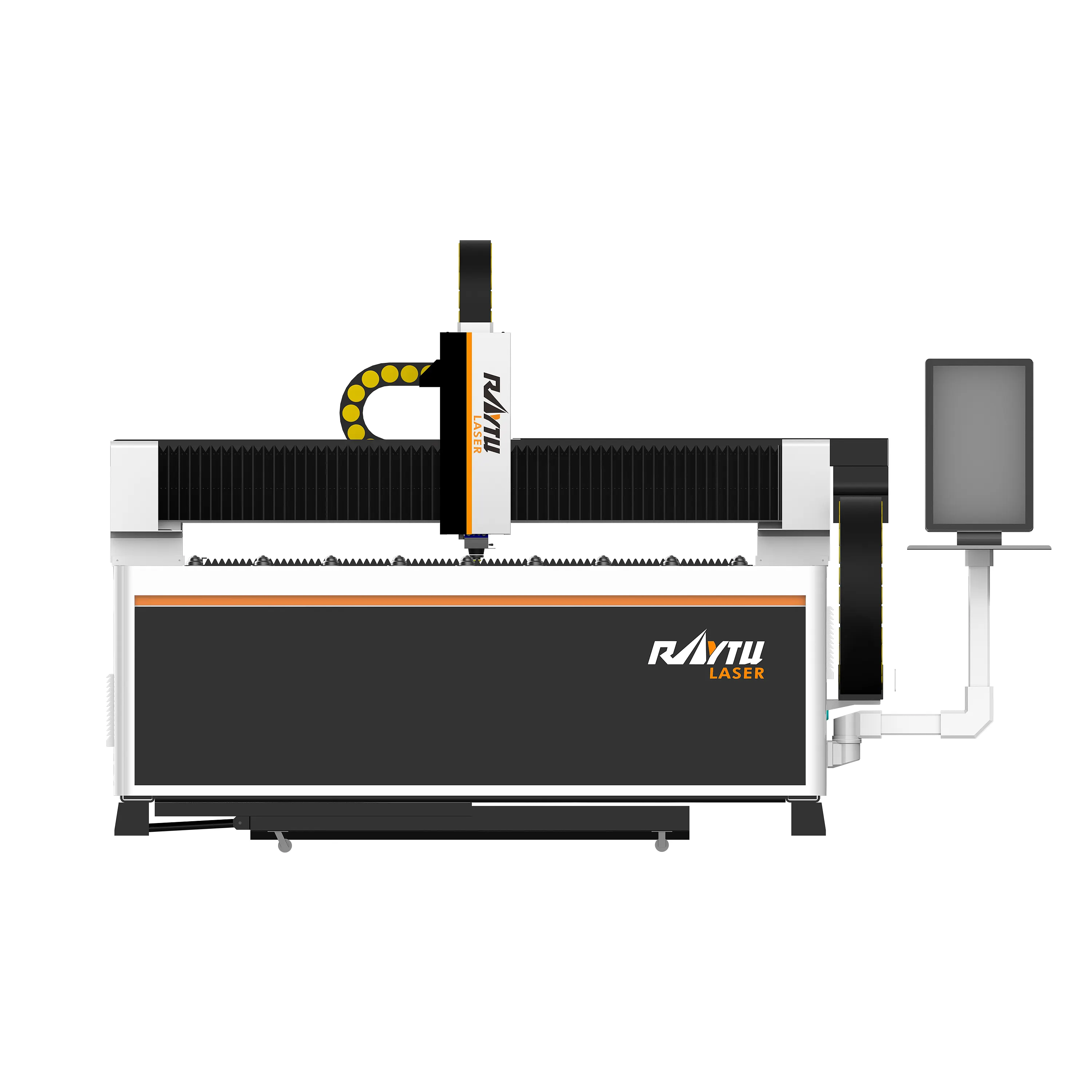

3 Aviation Aluminum Beam

The portal is made of aircraft grade aluminum, which has good acceleration characteristics. It has a gantry structure,

dual motors drive gantry synchronously, has high cutting speed, extremely low operating costs, excellent stability, high

processing quality and extremely high adaptability.

1. Aircraft extruded aluminum profile portal is finished after the process of extrusion molding, annealing,

vibration and natural aging, so that the overall rigidity and surface quality of the portal are very good, while

they have good strength and ductility.

2. The gantry structure, which is optimized by the finite element method based on the properties of the

aluminum alloy metal, is corrosion resistant, lightweight and very rigid, allowing for high speed travel during

laser cutting and excellent dynamic performance. Subject to accuracy, high-speed cutting of various graphics

is possible.

3.Aircraft aluminum gantry allows the equipment to have highly efficient dynamic characteristics, greatly

improve the processing efficiency and ensure the processing quality.

4 Raycus Laser Source

The RFL-C series source has the advantages of high efficiency of electro-optical conversion, good beam

quality, high energy density, wide modulation frequency, high reliability, long life and maintenance-free

operation.

It can be widely used in welding, precision cutting, cladding, surface treatment, 3D printing and other fields.

Its optical fiber output characteristics make it easy to integrate with robots into flexible manufacturing

equipment to meet the needs of 3D processing.

5 Raytools laser head

The Raytools cutting head is designed for industrial fiber lasers up to 6 kW.

Built-in double water cooling system ensures stable operation of the laser

head.

• Optimized optical configuration with efficient airflow distribution.

• Automatic focal length adjustment, human interference reduction, +10 -

12mm adjustable range, 10m / min focusing speed, 0.05mm precision,

0.05mm repeatability.

• Fast stitching, high speed cutting.

The pre-piercing time of 25mm carbon steel sheet is less than 3s (3000W),

which greatly improves the cutting efficiency.

• Large transparent diaphragm.

The transparent aperture is 35mm, which effectively reduces extraneous

light interference and ensures the quality and efficiency of cutting.

• High power

With the D37 optical lens group, it can handle up to 6kW of power, making

it easy to cut thick sheets.

• Lightweight and efficient

Product Recommendation