Application advantages of laser welding machine in aluminum alloy products

As a common raw material for industrial products, aluminum alloy products are important for reducing the power of the car body and preventing corrosion. Nowadays, the application range of alumimum alloy is very common. Especially in automobile manufacturing, such as engines, wheels, instrument panels, etc. The processing methods involved are welding and cutting. Due to the outstanding performance of the laser welding machine, not only the processing efficiency is improved, but the welding effect is very good, which helps to improve the craft level of the industry. The following describes the application of laser welding machine on aluminum alloy products.

Application of laser welding machine on aluminum alloy products

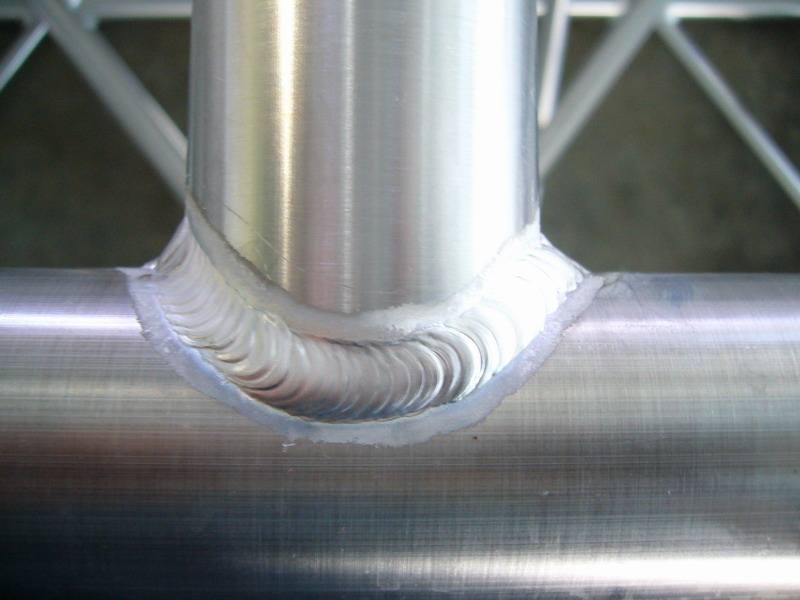

The laser welding machine for aluminum alloy products is realized by pulsed or continuous laser beam. Therefore, when the laser beam directly irradiates the surface of aluminum alloy, it can quickly diffuse the heat of the metal surface to the inside of the aluminum alloy, making the aluminum alloy rapidly melting to form a weld kerf, and at the same time a reaction force is formed on the melted metal, which dents the surface of the melted aluminum alloy to form small holes.

Application advantages of laser welding machine in aluminum alloy products:

1. High energy density, low heat input, small thermal deformation, narrow melting zone and heat-affected zone and large penetration depth. Raytu is one of the first batch of laser equipment manufacturers in China, with 16 years of R&D and production experience. Since its establishment, the company has always paid attention to the research and development of laser technology and the development needs of customers, and is committed to providing each customer with complete material processing solutions.

2. The high cooling rate results in a fine weld structure and good joint performance;

3. Compared with traditional welding, laser welding does not use electrodes, so it reduces man-hours and costs;

4. The vacuum atmosphere of electron beam welding is not required, and the shielding gas and pressure can be selected. The shape of the welded workpiece is not affected by electromagnetics and does not produce X-rays;

5. It can weld metal materials inside closed transparent objects;

6. The laser can be transmitted over a long distance with optical fiber, which makes the process adaptable. With the computer and manipulator, it can realize the automation and precise control of the welding process.

The above is the application of laser welding machine to aluminum alloy products. With the improvement of the popularization level of laser processing applications, laser welding machines are used to weld aluminum alloy products. The heat input is small and the heat source is concentrated, especially after the advent of fiber laser welding machines , the energy density of laser welding is more concentrated, the laser wavelength is shorter, and the high reflection is improved. Through laser wire filling, laser-MIG hybrid welding, dual-spot laser welding and other processes, the forming effect of aluminum alloy welding can be significantly improved, and the welding quality is improved.