The Ultimate Guide to Fiber Laser Cleaning Machine

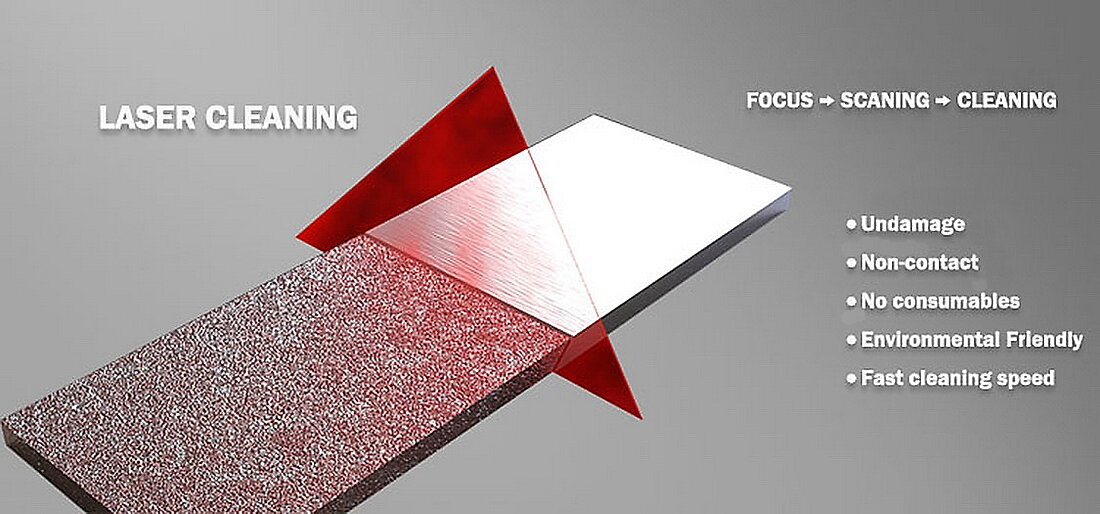

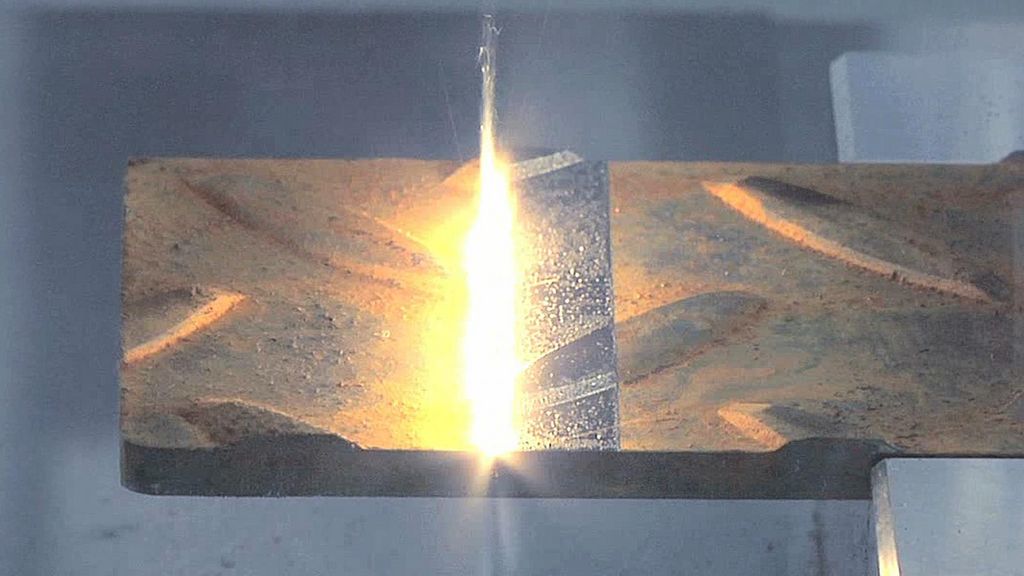

Fiber laser cleaning is an effective and efficient method to remove rust and oxide layers from the surface of metal materials. The laser with higher energy density interacts with specific substances, and the force generated by energy conversion overcomes the bonding force between the material to be cleaned and the substrate, and through the process of light peeling, vaporization, ablation, plasma impact, vibration, etc., the contaminants are separated from the material surface to achieve the purpose of cleaning, and the object to be cleaned is not damaged or the damage is controlled to the minimum.

In the high-end manufacturing industry, in order to ensure the quality of the industrial products during electroplating, phosphating, spraying, welding and assembly, it is necessary to remove the dirt, grease, dust, rust and other contaminants on the surface of the product. With high surface cleaning requirements, laser cleaning technology came into being. Laser cleaning machine is considered to be the most reliable and effective surface treatment technology due to its cleaning characteristics such as no force, no chemical reaction, no thermal effect and suitable for various materials. The following is an introduction to the status of the laser cleaning industry and analysis of the market prospects of laser cleaning machines.

Although the emergence of laser cleaning can be traced back to the 1960s, the research and application of this innovative cleaning technology has been gradually expanded since the 1990s. In the past 20 years, there have been reports on laser cleaning technology at home and abroad. In recent years, it has quickly become a research hotspot in the field of industrial manufacturing. The research content mainly covers laser cleaning technology, theory, equipment and applications.

In the field of industrial applications, with the rapid development of lasers and the continuous in-depth study of laser cleaning mechanisms, surface quality monitoring and characterization methods have become more complete and comprehensive, the surface quality of laser cleaning materials has been improved, and the cleaning accuracy and efficiency have gradually increased. Today, it has become a reliable technology that can clean the surface of a large number of different substrates. The cleaning objects include steel, aluminum alloy, titanium alloy, glass and composite materials, etc. The application industries cover aerospace, aviation, shipbuilding, high-speed rail, automobiles, molds, nuclear power and Ocean and other fields.

Current status of laser cleaning industry

Laser cleaning is a new application technology that is closest to the international frontier in the field of laser application technology. The domestic structure is divided into three parts: customers, research institutions and companies.

Domestic universities and research institutes started early, but real attention to the market has also begun in recent years with the rapid development of fiber laser technology. Industry companies are divided into three categories: laser manufacturers, small and medium-sized sales companies, and professional equipment manufacturers. The upstream laser manufacturers are strong, the downstream sales companies are not evenly developed, and there are not many professional laser cleaning equipment manufacturers. There are still a large number of laser marking companies on the sidelines.

2018 is a good year for laser cleaning. Many companies want to use laser cleaning as a new growth point for their companies, but they dare not make a big investment easily. Especially for a large number of laser marking companies, the risk of transformation is very high. Based on the current market situation, industry development guidance is needed at this time. Fortunately, many experts in the industry have done a lot of work in this area. For example, they have promoted the funding of laser cleaning equipment projects in the country and Guangdong Province.

In terms of practical application, there is a large gap between domestic and foreign countries. This is caused by many reasons. In addition to the immature laser cleaning mechanism and technology, the equipment also limits the improvement of laser cleaning efficiency and accuracy.

The chracteristics of fiber laser cleaning machine

1 High efficiency

Under the action of high-temperature energy, the deposits instantly vaporize and evaporate off the surface of the object, and the time required is very short. The traditional cleaning methods, such as ultrasonic cleaning, can only be cleaned after preheating and cooling, which takes a long time.

2 More environmentally friendly

Laser cleaning is a "green" cleaning method that does not need to use any chemicals and cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, no photochemical reaction and no pollution . It can easily solve the environmental pollution problem caused by chemical cleaning. Often a single exhaust fan can solve the problem of waste generated by laser cleaning.

3 Low cost

Laser cleaning is fast, efficient, and time-saving; although the purchase of a laser cleaning system has a high initial investment, the cleaning system can be used stably for a long time, with low operating costs, and more importantly, it can be easily automated.

4 More convenient

Laser cleaning can remove various types of contaminants on the surface of various materials to achieve a cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean the contaminants on the surface of the material without damaging the surface of the material.

5 Good results

The traditional cleaning method is often contact cleaning, which has a mechanical force on the surface of the cleaning object, damages the surface of the object or the cleaning medium adheres to the surface of the object to be cleaned, resulting in secondary pollution. The non-abrasive, non-contact, and non-thermal effects of laser cleaning will not damage the substrate, making these problems easy to solve.

6 Convenient control

The laser can be transmitted through optical fiber and cooperate with the robot, it is convenient to realize long-distance operation, and can clean the parts that are not easy to reach by traditional methods. You can choose the corresponding pulse frequency, energy and wavelength according to the material at will to achieve better results.

7 High security

Long-distance operation, no harmful substances and gases. Ensure the safety of operators

8 No wear

The cleaning process is non-contact and will not cause any wear on the surface of the base metal.

The market prospect of laser cleaning machine is broad. Daily industrial products and professional industrial products must use one or several of the surface treatment technologies to realize the functions required by the product design or the market. In the process of electroplating, phosphating, spraying, welding, packaging and integrated circuit assembly of industrial products, grease, dust, rust, residual solvents, adhesives and other dirt on the surface must be removed to ensure the quality of the next process . The current cleaning methods widely used in the cleaning industry include mechanical cleaning, chemical cleaning and ultrasonic cleaning, but their application is greatly restricted under the constraints of environmental protection and the requirements of the high-precision market. The laser cleaning machine has obvious advantages in various industries.

1. Mold cleaning

Every year, tire manufacturers all over the world manufacture hundreds of millions of tires. The cleaning of tire molds during the production process must be rapid and reliable to save downtime. Traditional cleaning methods include sandblasting, ultrasonic or carbon dioxide cleaning, etc. usually have to cool the high-heat mold for several hours before moving it to the cleaning equipment for cleaning. The cleaning takes a long time and easily damages the accuracy of the mold. Chemical solvents and noise will also cause safety and environmental issues.

It is flexible in using the laser cleaning method, because laser cleaning can be connected to the optical fiber, the light guide can be cleaned to the dead corner of the mold or the part that is not easy to clean, so it is convenient to use; No gasification, so no toxic gas will be produced, which will affect the safety of the working environment.

The technology of laser cleaning tire molds has been widely adopted in the tire industry in Europe and the United States. Although the initial investment cost is relatively high, the benefits of saving standby time, avoiding mold damage, working safety and saving raw materials can be quickly recovered.

According to the cleaning test conducted by Raytu laser on the production line of a tire company in Shandong, it only takes 1.5 hours to clean a set of large truck tire molds online. Compared with conventional cleaning methods, the economic benefits are obvious.

2. Cleaning of weapons and equipment

Laser cleaning technology is widely used in weapon maintenance. The laser cleaning system can remove rust and pollutants efficiently and quickly, and can select the removal part to realize the automation of cleaning. Using laser cleaning, not only the cleanliness is higher than the chemical cleaning process, but also almost no damage to the surface of the object.

By setting different parameters, a dense oxide protective film or molten metal layer can also be formed on the surface of the metal object to improve the surface strength and corrosion resistance. The waste material removed by the laser basically does not pollute the environment, and it can be operated remotely, effectively reducing the health damage to the operator.

3. Cleaning of old aircraft paint

In Europe, laser cleaning systems have long been used in the aviation industry. The surface of the aircraft must be repainted after a certain period of time, but the original old paint needs to be completely removed before painting. The traditional mechanical paint removal method can easily damage the metal surface of the aircraft and bring hidden dangers to safe flight. If multiple laser cleaning equipment are used, the paint layer on the surface of an A320 Airbus can be completely removed within two days without damaging the metal surface.

4. Cleaning of external walls of buildings

With the rapid development of economy, more and more skyscrapers have been built, and the problem of cleaning the exterior walls of buildings has become increasingly prominent. The laser cleaning system provides a good solution for cleaning the exterior walls of buildings through optical fibers. Effectively clean various contaminants on various stones, metals, and glass, and the efficiency is many times higher than that of conventional cleaning. It can also remove black spots and stains on various stones of buildings.

5. Cleaning in the electronics industry

The electronics industry uses lasers to remove oxides: The electronics industry requires high-precision decontamination, and lasers are particularly suitable for oxide removal. Before the circuit board is soldered, the component pins must be thoroughly deoxidized to ensure the best electrical contact, and the pins must not be damaged during the decontamination process. Laser cleaning can meet the requirements of use, and the efficiency is very high, a stitch only needs to be irradiated with the laser once.

6. Precise deesterification cleaning in the precision instrument industry

The precision machinery industry often needs to remove the esters and mineral oils used for lubrication and corrosion resistance on the parts, usually by chemical methods, and chemical cleaning often still has residues. Laser deesterification can completely remove esters and mineral oil without damaging the surface of the part. The removal of pollutants is accomplished by shock waves, and the explosive gasification of a thin layer of oxide on the surface of the parts forms a shock wave, which results in the removal of dirt instead of mechanical interaction. The material is thoroughly deesterified and used for the cleaning of mechanical parts in the aerospace industry. Laser cleaning can also be used to remove oil and ester in the processing of mechanical parts.

7. Cleaning of pipelines in nuclear power plant reactors

The laser cleaning machine is also used in the cleaning of pipelines in nuclear power plant reactors. It uses optical fibers to introduce high-power laser beams into the reactor to directly remove radioactive dust, and the cleaned materials are easy to clean. And because it is operated remotely, the safety of the staff can be ensured.

8. Cultural relic cleaning and protection

Internationally, laser cultural relic cleaning and protection technology has been widely used in the cleaning and protection of museum cultural relics and buildings. Many examples have proved that laser cleaning is an effective method for the cleaning process of cultural relics and paintings. The washing mechanism is based on the cold ablation that breaks the bond, and its thermal effect is small or negligible. Will not cause thermal damage to the artwork itself.

Since civilian laser products have very high requirements for laser protection and safety, the current laser cleaners do not have mature conditions for entering the civilian market.

Compared with traditional cleaning technology, laser cleaning technology has great advantages in terms of economic benefit, cleaning effect or "green engineering", and has a broader market prospect. Raytu team will be glad to be at your service if you need any professional advice on fiber laser cleaning.