The operation procedure of laser cutting machine

Metal material is an important product in the manufacturing industry. If we want to make full use of this material, it must be cut and formed with equipment. Laser cutting machine is an important mechanical equipment in the metal forming industry. Compared with other types of cutting machine, laser cutting machine has a high degree of automation, can be applied to a wide range of cutting efficiency and higher cutting precision, so it is widely popular in the manufacturing industry.

Laser cutting machine as a metal cutting tool, want to give full play to its work efficiency, we need to master its working principle and operation steps. Today, we will learn how to operate the laser cutting machine.

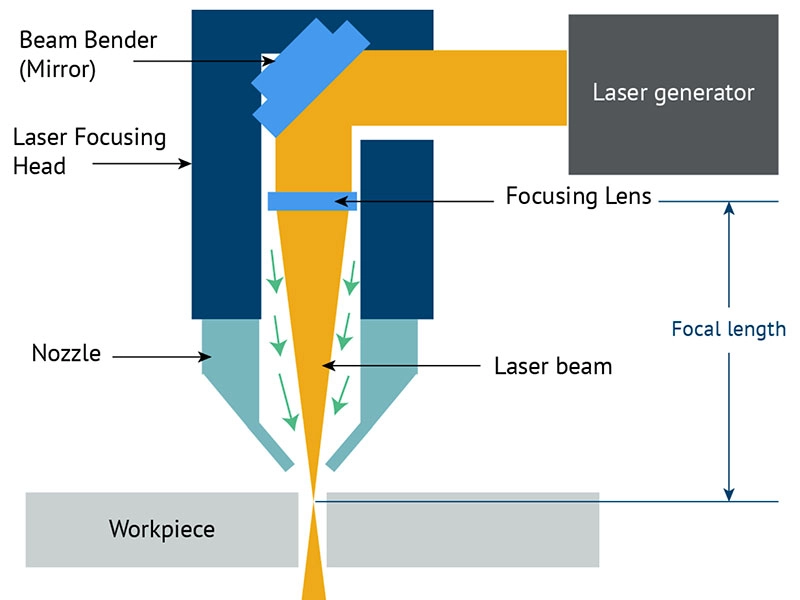

Principle of work is not hard to understand of the metal laser cutting machine, laser cutting machine is used by focusing on the high power laser beam of high energy density of artifacts, cause the irradiation materials rapidly melting, evaporation and ablation or reach the ignition point, at the same time with the aid of high pressure with beam coaxial high-speed airflow blow molten material, cut so as to realize the workpiece.

To operate a metal laser cutter, the following steps are usually required:

1. Open the working circuit of each part, including the general power switch, voltage regulator, fiber laser power switch, air compressor, air valve, cold dry machine, etc., to ensure that the power supply system of each part is normal;

2. Test run the machine to make sure that the machine runs smoothly and the limits and emergency buttons are secure;

3. Put the material to be cut on the machine tool cutting table smoothly, operate the console computer screen at the same time, input the product material thickness and other parameters, and import the pattern into the machine;

4. Control the movement of each axis through the functions in the menu, and adjust the cutting position to the appropriate part of the plate;

5. Select appropriate sprinkler heads and lenses and check them to ensure that their appearance and cleaning condition are in good condition; Adjust the cutting head to the appropriate cutting focus position by using the arrow keys on the panel;

6. According to cutting requirements, select suitable cutting gas, and check whether its injection state is good;

7. Start the laser and machine tool, test cutting metal raw materials, observe whether the section is smooth, cutting accuracy is accurate, if there is a deviation, adjust the equipment parameters, until the proofing meets the requirements; Then the equipment automatically starts cutting according to the input parameters and patterns;

8. During the cutting process, there must be staff present. If there is an emergency and a quick response is needed, the staff need to press the brake button quickly;

9. After finishing the cutting work, pay attention to check the cutting precision and quality of the product;

In addition, after the fiber laser cutting machine is used, it is necessary to shut down the machine, so as to reduce the fault of the fiber laser and increase the service life of the machine. The specific operations are as follows:

(1) Turn off the laser.

(2) Turn off the water cooler.

(3) Turn off the gas in the exhaust pipe.

(4) Lift the Z axis to a safe height, turn off the numerical control system, and seal the nozzle with transparent glue to avoid dust contamination of the lens.

(5) Clean up the site and record the operation of the cutting machine on the day. If there is a fault, it should be recorded in time for maintenance personnel to carry out diagnosis and maintenance.

(6) When the laser cutting machine is idle, the staff need to ensure that the equipment is clean, often clean the guide rail, wipe the rack of the equipment, and apply lubricating oil.

It is worth noting that in the operation of metal laser cutting machine, in addition to strictly follow the operating procedures, but also should do a good job of personal protection, such as in the vicinity of the laser beam, to wear the required protective glasses, to avoid unnecessary risks. If you are a novice operator, you must consult all the relevant instructions, or after professional training, do not use randomly, disorderly operation.