Three Advantages of 20000W Laser Sources

The following are the three main advantages of 20KW fiber laser sources.

Advantage 1: 40 meters long fiber optic cable

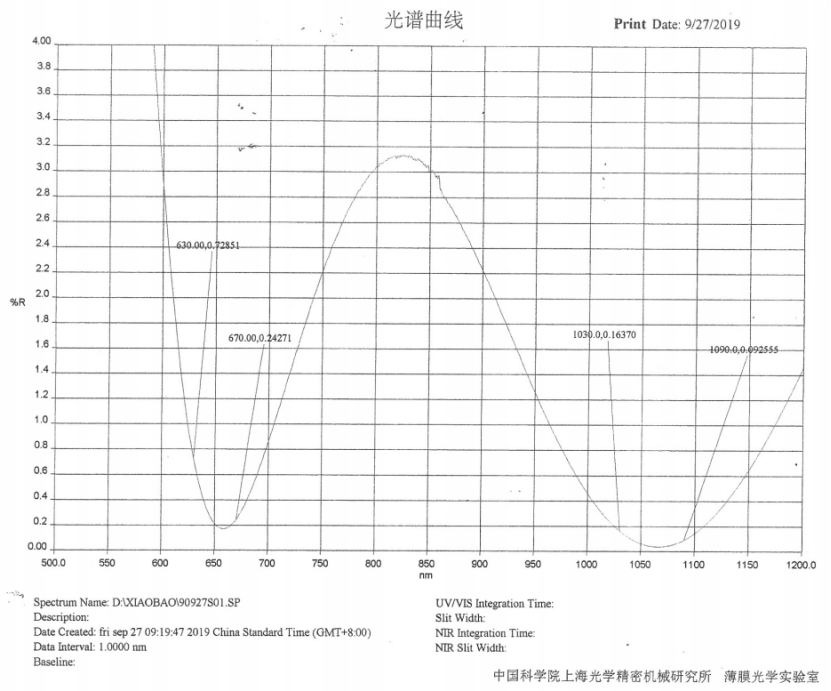

As we all know, the length of the optical cable is essentially limited by the nonlinearity of the laser (Raman scattering). The longer the output optical cable, the stronger the Raman, which affects the application effect and safety and reliability of the laser source. Due to the influence of Raman, the length of the output optical cable is generally not more than 25m for laser sources of the same specification currently on the market. For the 20000W laser, the 100μm fiber laser with the output of 40m long optical cable is developed and launched and the MOPA structure is adopted. Compared with the oscillating structure, the power tolerance of each part of the optical components is reduced. The core components are strictly selected. The BPP control has high consistency and the ratio of Raman suppression is ≥35dB, which truly improves the reliability and stability of the laser source and leads the new development of high-performance laser processing.

Advantage 2: Reduce the difficulty of coating, highly adaptable to optical devices, more stable and reliable

The typical signal light center wavelength of industrial high-power lasers is 1080nm, and the anti-reflection coating plated on the related optical devices on the optical path is for the center wavelength ±20-30nm. When stimulated Raman scattering (SRS) exceeds the threshold, first-order Raman light (central wavelength 1130 nm) with a difference of 50 nm from the central wavelength of the signal light will be generated, which requires an antireflection coating to cover this band at the same time. In order to achieve high transparency in a wide wavelength range, it is necessary to coat more layers of film to achieve. However, we know that the more layers of film, the more difficult it is to improve the laser damage threshold, and it will also affect the long-term reliability. The excellent nonlinear suppression technology of the 20000W laser can make the center wavelength of the output light at 1080±10nm, and the related optical devices can be coated with a few layers of anti-reflection coating to meet the requirements, which reduces the difficulty of coating and greatly improves the stability and reliability of the optical devices. Reliability further improves the efficiency of laser processing.

Advantage 3: The cutting speed is increased by an average of 32%

At present, the long fiber optic cable 20000W laser has been verified by both stability and reliability on the application side. In terms of cutting stainless steel, the current test thickness reaches 80mm, and the cutting speed is 20%-66% higher than the conventional one. Brighter brightness, higher reliability, longer optical cable, calmly cope with high power and large format, not limited by the size of the processing machine, it will be suitable for a wider range of application scenarios, saving more labor and material costs for customers, greatly Improve processing efficiency and bring higher benefits.