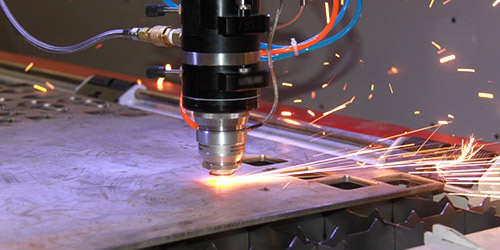

30kW, 40kW laser cutting equipment is born, is power really the king?

The article is about the choice of fiber laser cutting machine and rational thinking of laser cutting equipment market.

At an exhibition in Shanghai in 2019, the main laser cutting equipment enterprises are still scrambling to launch 20kw power machine, and even claim to have 30kW and 40kw equipment. By this year, they have launched 30kW or even 40kW equipment, which seems to be a bit addicted to power pursuit.

It is undeniable that domestic brands have made important contributions to the development of fiber lasers, and opened more application space and possibilities for laser processing. There is no denying that the increase of power will bring higher processing efficiency. For the same thickness of metal plate, the processing speed and efficiency of the most popular 12KW laser cutting machine with ultra-high power is almost twice that of 6kW. With the continuous improvement of the performance and efficiency of high-power fiber laser, the efficiency of laser processing is greatly improved, which may be used to manufacture general tools for large-scale production in the future.

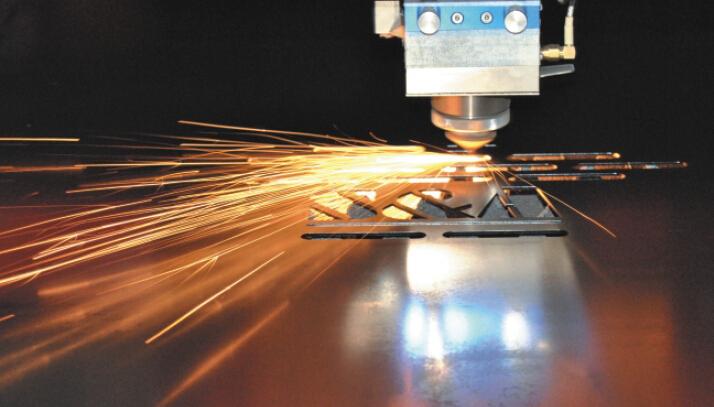

However, we must see that the metal materials with a thickness of more than 40mm are mostly used in high-end equipment, large components, special fields and special applications. For most common products in life and industrial manufacturing, the laser processing demand is within 20 mm, which is exactly the range of 2000 to 6000 watt laser. On the one hand, we can see that foreign enterprises such as Trumpf, Bytronic, Mitsubishi, Mazak, etc. do not deliberately pursue rendering 10000 watt cutting equipment, but focus on recommending appropriate power according to the processing conditions of users. On the other hand, we also see that users gradually become rational, and the market choice gradually shows that the sales growth of cutting equipment above 10000 watt level has not reached the expectation, but the medium and high power 2kw to 6kW has increased rapidly.

Laser manufacturers are still working hard to improve the power of the laser source, but having this power capability does not mean that the market can support the expansion. In addition, whether the power carrying capacity of optical devices and supporting integrated products can follow up is also a big problem. In addition, to improve the processing speed is not to blindly improve the power, but also from the integrated machine tool, control system, platform, the whole body design and other mechanical factors. Users are very clear about their products and processing needs. They will ultimately choose the power band that meets their own application rationally. What they value most is the stability of high-power machines and the ability of continuous processing.