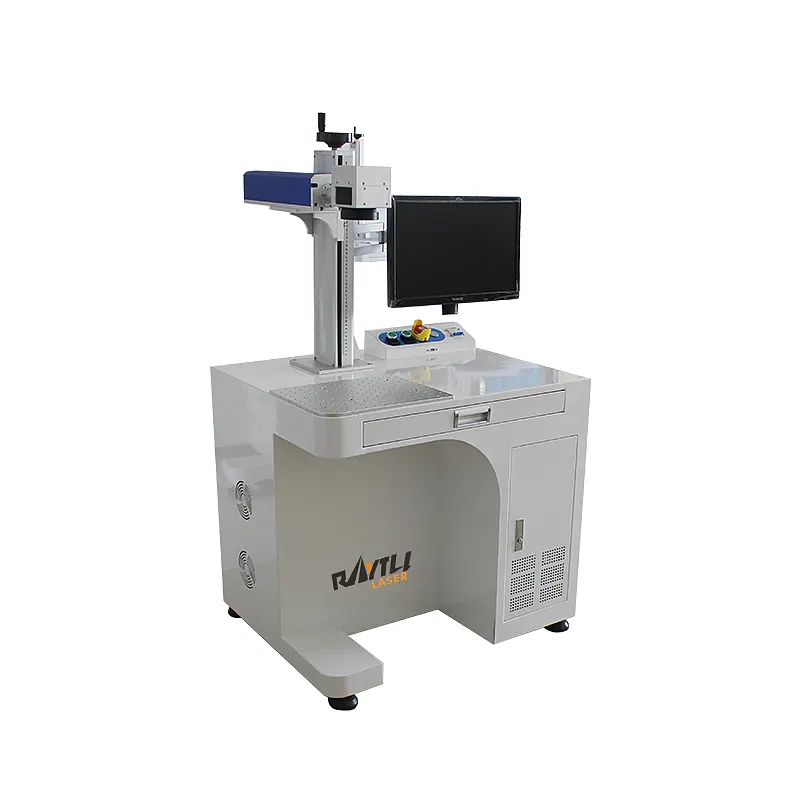

Optical Fiber Laser Marking Machine

Description

Raytu Fiber laser marking machine uses fiber laser source to output energy, and then scanning galvanometer system is used to realize a permanent mark on various material surfaces. The electro-optic conversion efficiency of optical fiber marking is as high as 30%. The main effects of laser marking machine are as follows: the deep layer of the material is exposed through the evaporation of laser energy on the surface of the target material; "engrave" the required patterns and characters through the chemical and physical changes of the surface material by laser light energy; part of the material can be burned off by laser light, so as to show the pattern and text to be etched.

Features

1. Long service life and high beam quality

The life span of fiber laser source up to 100000 hours. The beam quality is high, it is the fundamental mode (TEM00) output, and the focused spot diameter is less than 20um. The divergence angle is 1/4 of the diode pumped laser, which is especially suitable for fine and precise marking.

2. Save water and electricity

Small size, low power consumption. The power consumption of the whole machine is less than 500W; the built-in air cooling mode abandons the bulky water cooling unit, smaller footprint, and easier installation.

3. High electro-optic efficiency

Electro optic conversion efficiency is high, simple and easy to use, no optical adjustment or maintenance needed, compact structure, high system integration, less failure.

4 Maintenance free function

No need for any maintenance, long service life, suitable for harsh environment.

5. Fast processing speed

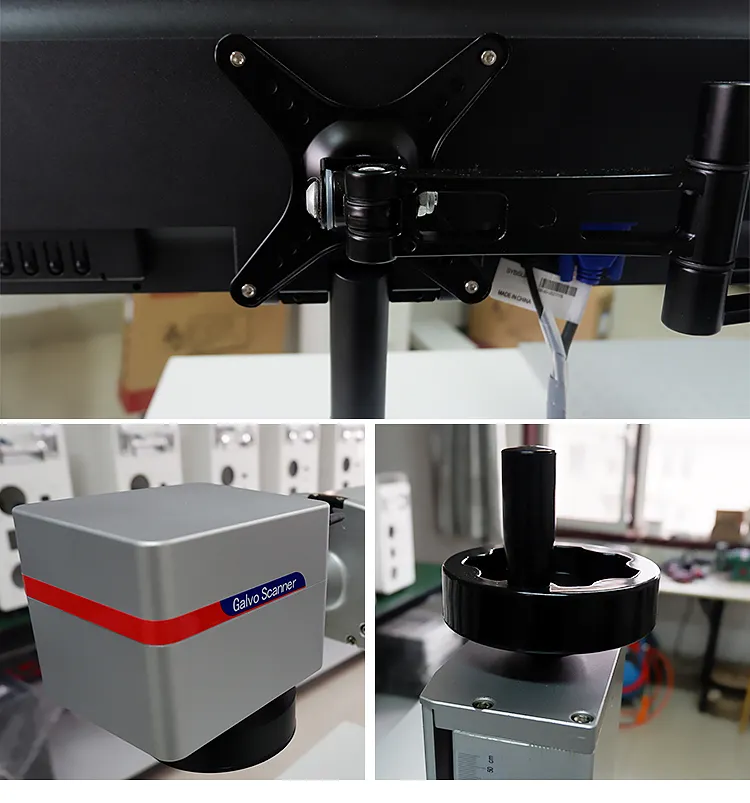

High processing speed is 2-3 times of the traditional marking machine, optical scanning galvanometer, high laser repetition frequency, high speed without distortion.

6. Large application areas

All fiber lasers are equipped with optical isolators, which can effectively shield the reflected light. They can be operated on high reflective materials such as gold, silver, copper, aluminum, silicon and so on. They do not need to deviate from the center of the field mirror, which greatly broadens the application field.

7. Powerful software

The marking software has powerful functions and can be compatible with files of CorelDRAW, AutoCAD and other software; it supports PLT, PCX, DXF, BMP and so on, and can directly use SHX and TTF font library; it supports automatic coding, printing serial number, batch number, date, bar code, two-dimensional code, automatic number skipping and so on, and USB interface output control.

What Materials can Raytu laser marking machine mark:

Raytu Laser Marker Parameters

Product Recommendation