Six most useful fiber laser cutting machine functions you need know

In recent years, the role of fiber laser cutting machines in the development of the sheet metal industry has become increasingly prominent. In terms of powerful cutting performance, Raytu Laser wants to introduce six little-known practical functions to everyone. With these practical functions, it can greatly improve the processing efficiency and cutting performance of fiber laser cutting machines.

1. Leapfrog

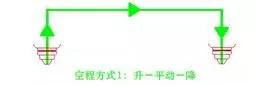

Leapfrog is the idle way of laser cutting machine. As shown in the figure below, after cutting hole 1, then cutting hole 2. The cutting head must move from point A to point B. Of course, the laser must be turned off during the movement. The movement process from point A to point B, the machine runs "empty", which is called idling.

The idle stroke of the early laser cutting machine is shown in the following figure. The cutting head must complete three actions: ascending (to a sufficiently safe height), translation (arriving above point B), and descending.

The idle time can be compressed to improve the efficiency of the machine. If the three actions are completed "simultaneously", the idle time can be shortened: when the cutting head starts from point A to point B, it rises at the same time; when it approaches point B, it falls at the same time. As shown below.

The trajectory of the cutting head's idle motion is like an arc drawn by a frog jumping.

In the development process of laser cutting machine, the leapfrog can be regarded as an outstanding technological advancement. Leapfrogging only takes up the translational time from point A to point B, and saves the time of ascent and descent. The frog jumped and caught the food; the frog jump of the laser cutting machine "caught" high efficiency. If the laser cutting machine does not have the leapfrog function, I am afraid it will not enter the market.

2. Auto focus

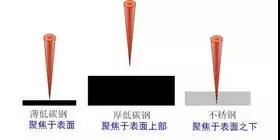

When cutting different materials, the focus of the laser beam is required to fall on different positions of the cross-section of the workpiece. As shown below.

Therefore, it is necessary to adjust the position of the focus (focus). Early laser cutting machines generally used manual focusing; now, many manufacturers' machines have achieved automatic focusing.

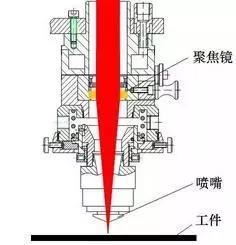

Some people may say that it is enough to change the height of the cutting head. When the cutting head is raised, the focus position will be higher, and when the cutting head is lowered, the focus position will be lower. It's not that simple.

The bottom of the cutting head is a nozzle. During the cutting process, the distance between the nozzle and the workpiece (nozzle height) is about 0.5~1.5mm. It may be regarded as a fixed value, that is, the nozzle height does not change, so the focus cannot be adjusted by lifting the cutting head (otherwise the cutting process cannot be completed).

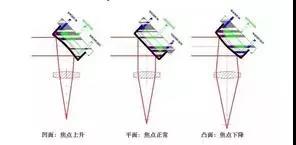

The focal length of the focusing lens is immutable, so you cannot expect to adjust the focus by changing the focal length. If you change the position of the focus lens, you can change the focus position: the focus lens goes down, the focus goes down, and the focus lens goes up, the focus goes up. ——This is indeed a way of focusing. A motor is used to drive the focusing lens to move up and down to achieve automatic focusing.

Another automatic focusing method is: before the beam enters the focusing mirror, a variable curvature mirror (or adjustable mirror) is set, and the divergence angle of the reflected beam is changed by changing the curvature of the mirror, thereby changing the focus position. As shown below.

With the automatic focusing function, the processing efficiency of the laser cutting machine can be significantly improved: the perforation time of thick plates is greatly reduced; when processing workpieces of different materials and thicknesses, the machine can automatically quickly adjust the focus to the most suitable position.

3. Automatic edge finding

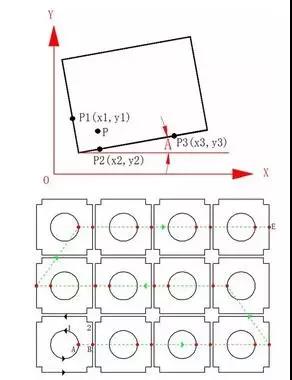

As shown in the figure below, when the sheet is placed on the worktable, if it is skewed, it may cause waste during cutting. If the inclination angle and origin of the sheet can be sensed, the cutting process can be adjusted to suit the angle and position of the sheet to avoid waste. The automatic edge finding function came into being.

After the automatic edge finding function is activated, the cutting head starts from point P and automatically measures 3 points on the two vertical edges of the sheet: P1, P2, P3, and automatically calculates the inclination angle A of the sheet and the origin.

With the help of the automatic edge seeking function, it saves the time of adjusting the workpiece earlier-it is not easy to adjust (move) workpieces weighing hundreds of kilograms on the cutting table, which improves the efficiency of the machine.

A high-power laser cutting machine with advanced technology and powerful functions is a complex system integrating light, machine and electricity. The subtlety often hides the mystery. Let us explore the mystery together.

4. Concentrated piercing

Centralized perforation, also called pre-perforation, is a processing technology, not a function of the machine itself. When fiber laser cutting thicker plates, each contour cutting process has to go through two stages: 1. perforation and 2. cutting.

Conventional processing technology (A point perforation→cut contour 1→B point perforation→cut contour 2→……). The so-called centralized perforation is to perform all the perforation processes on the entire board in advance, and then perform the cutting process again.

Concentrated perforation processing technology (complete perforation of all contours→return to the starting point→cut all contours). Compared with the conventional processing technology, the total length of the machine's running track is increased during concentrated perforation. Then why use concentrated piercing?

Concentrated perforation can avoid over-burning. During the perforation process of the thick plate, heat accumulation is formed around the perforation point. If it is cut immediately, overburning will occur. The centralized perforation process is adopted to complete all perforations and return to the starting point for cutting. Since there is sufficient time to dissipate heat, overburning is avoided.

Centralized perforation can improve processing efficiency. At present, there are still many fiber laser cutters that do not have the function of automatic focusing. The process parameters (laser mode, power, nozzle height, auxiliary gas pressure, etc.) of perforating and cutting of thick plates are different. The height of the nozzle during the piercing process is higher than that of the cutting process. If the conventional processing technology is adopted (contour 1 perforation→contour 1 cutting→contour 2 perforation→contour 2 cutting→……), in order to ensure the cutting quality and efficiency, the position of the laser beam can only be manually adjusted according to the cutting needs(Imagine if this is the case: at first, manually set the focus to the position required for the piercing, pierce; then, adjust the focus to the position required for cutting, cut; then adjust to the pierce position, pierce; ...; Until the processing is completed-this is simply a nightmare). Therefore, the focus during perforation must not be at the optimal position, and the perforation time is longer. However, if the centralized perforation method is adopted, the focus can be adjusted to a position suitable for the perforation first, after the perforation is completed, the machine is paused, and then the focus position is adjusted to the best position required for cutting; in this way, the perforation time can be shortened by more than half and greatly improve efficiency. Of course, if necessary, other process parameters can be adjusted or changed between concentrated piercing and cutting (for example, air + continuous wave can be used for piercing, and oxygen can be used for cutting, and there is enough time to complete the gas switch). We generally call the automatic zoom of the driving focus lens the F axis; like this, the manual zoom is used to concentrate the piercing and cutting, can it be called the "H" (Hand) axis "zoom"?

There is also a risk of concentrated perforation. If a collision occurs during the cutting process, which causes the position of the plate to change, the part that has not been cut may be scrapped. The centralized perforation process requires the help of an automatic programming system.

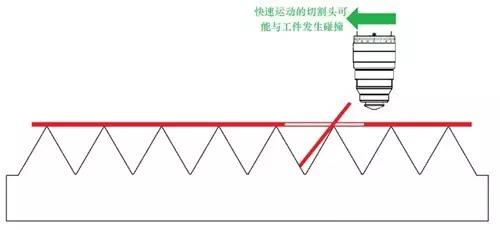

5. Bridge position (micro connection)

During the laser cutting process, the sheet material is supported by the serrated support bar. If the cut part is not small enough, it cannot fall from the gap of the support bar; if it is not big enough, it cannot be supported by the support bar; it may lose its balance and warp. The cutting head moving at high speed may collide with it, and the cutting head may be damaged in the light of the shutdown.

The use of bridge (micro-connection) cutting technology can avoid this. When programming the graphics for laser cutting, the closed contour is intentionally broken in several places so that after the cutting is completed and the parts adhere to the surrounding materials without falling. These broken places are the bridges. Also known as breakpoint, or micro-connection (this name is derived from the blunt translation of MicroJoint). The distance of the break, about 0.2~1mm, is inversely proportional to the thickness of the sheet. Based on different angles, there are these different names: based on the contour, it is disconnected, so it is called a breakpoint; based on the part, it is adhered to the base material, so it is called a bridge or a micro-connection.

The bridge position connects the parts with the surrounding materials. The mature programming software can automatically add the appropriate number of bridge positions according to the length of the contour. It can also distinguish the inner and outer contours, and decide whether to add bridges, so that the inner contours (waste) that do not leave the bridges will fall, and the outer contours (parts) of the bridges will be glued together with the base material and will not fall, thereby avoiding sorting work.

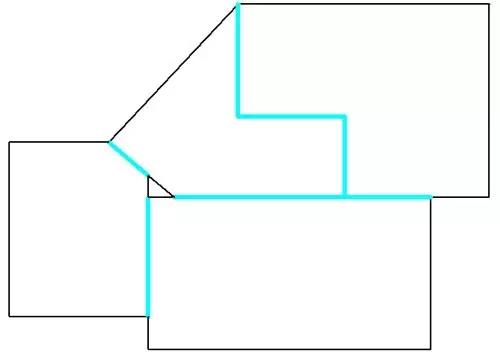

6. Common edge cutting

If the contours of adjacent parts are straight lines and the angles are the same, they can be merged into a straight line and only cut once. This is the common edge cutting. Obviously, co-edge cutting reduces the cutting length and can significantly improve processing efficiency.

Common edge cutting does not require the shape of the part to be rectangular. As shown below.

The sky blue lines are common edges, and the common edges cut can not only saves the cutting time, but also reduces the number of perforations. Therefore, the benefits are very obvious. If you save 1.5 hours a day due to common edge cutting, about 500 hours are saved every year, and the hourly comprehensive cost is 100$, which is equivalent to creating an additional 50,000$ benefit a year. Common edge cutting needs to rely on intelligent automatic programming software.